Iyini imbangela yokwehluleka ukugqwala kwe-valve?

Ukuze uvumelane nokusetshenziswa kwamathuluzi womoya wokulungisa, ububanzi bepayipi kanye ne-valve enqanyuliwe yepayipi lomoya elicindezelwe esiteshini somphakathi kungandiswa ngokufanele, isibonelo, i-DN25 inyuswe kumishini ye-DN50, kanye nejoyinti yepayipi ehambisana ne isiteshi somphakathi singabiwa ne-exhaust yepayipi lemishini; Ekufakweni okukhulu, imbobo yokuxhuma impahla evamile (UC) ingase ihlinzekwe ezintweni zokusebenza. Imbobo yokuxhuma kanye nevalvu yokukhipha umoya kuzotholakala engxenyeni engezansi nengaphezulu yempahla eqondile noma kuzo zombili iziphetho zobude bendawo yokusebenza evundlile ngokulandelana. Lapho ipayipi lempahla evamile lingangcoliswa ukugeleza koketshezi oluqhubekayo, amavalvu okuhlola kufanele abekwe ezansi nomfula ovamile wokunqamula amapayipi.

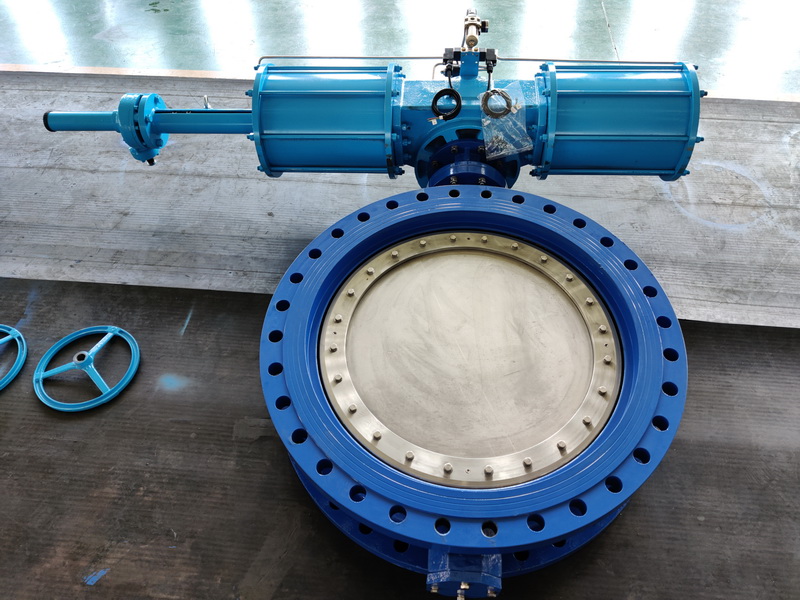

Ukuxhuma: Ukusetha okuyisisekelo kwe-valve

Uchwepheshe besistimu yenqubo yamakhemikhali ekwakhiweni kwe-boiler yokushisa imfucuza ephezulu nesistimu yesitimu, ingabhekisa kumandla aphezulu

Izinhlinzeko ezifanelekile zoMnyango Wezimboni kanye Nehhovisi Lokwakha Amandla:

Imithetho Yezobuchwepheshe Yokuklanywa Kwamapayipi Amanzi Ashushu Ezimbonini Zamandla Ashisayo (DLGJ 233-81)

I-Athikili 7~7 1: Pg≥40 ukugeleza kwamapayipi namanzi kufanele kusethwe ngochungechunge ngamavalvu okumisa amabili.

I-Athikili 7~8 1:Pg≥40 “esisetshenziswa sepayipi lepayipi, amavalvu okumisa amabili azosethwa ngochungechunge.

Iyunithi ye-off pressure ngu-kg/cm2(ithebula).

Uma usebenzisa, sicela unake izinhlinzeko zenguqulo ye-***.

Ngama-hydrocarbon, amakhemikhali anobuthi nayingozi nezinye izinto kanye nezinye izinto zenqubo yokuxhuma phezulu nomfula, ipayipi lokungenisa umoya lisethi amavalvu akabili, lingabhekisela kuThebula 2.0.3

Ithebula 2.0.3 izinga lokushisa kanye nezimo zengcindezi yamavalvu amabili

Isiteshi sempahla yomphakathi (isiteshi sobunjiniyela bomphakathi) Isiteshi sempahla yomphakathi (isiteshi esivamile ngamafuphi) embonini yamakhemikhali singasethwa ngokuya ngendawo ehlanganisa indawo engaba ngu-15m, kuyilapho isiteshi somphakathi esingaphandle kwendawo yezitshalo singasethwa ngokuvumelana ezidingweni zokuklama. Ukucaciswa kwe-valve esikiwe ye-medium ngayinye ukusuka ku-DN15 kuya ku-DN50 kuncike ezicini zedivayisi.

Ama-valve namajoyinti ezinto zomphakathi esiteshini angase angahambisani ngamabomu, futhi ukuhleleka kwabezindaba esiteshini somphakathi ngasinye kufanele kuhambisane, ukuze kugwenywe ukwanda kwengozi yendawo engalungile esimweni esiphuthumayo.

Amapayipi amanzi eziteshini zomphakathi ezingaphandle ezindaweni ezibandayo angenziwa ngale ndlela elandelayo:

(1) Uhlaka olunezingqimba eziningi: ngokusho kwevalvu yokubeka ipayipi evamile, nqamula eduze nomhlabathi ophansi bese usetha ilunga elisheshayo, lapho usebenzisa amanzi aphuma emthonjeni wamanzi oseduze. Uma kusetshenziswa ipayipi elingaguquki kanye ne-valve yokudonsa, i-valve yokudonsa kufanele ibekwe ku-valve kahle.

(2) Ethangini lokugcina noma indawo yokulayisha neyokuthulula, indawo yomthombo wevalvu ingalungiswa kahle ngokubonisana nabachwepheshe bokuhlinzeka ngamanzi kanye nokukhipha amanzi, futhi ivalvu yokuphakela amanzi ingatholakala emthonjeni wevalvu.

(3) Ukugcina ukushisa ngepayipi lesitimu.

Ukuze uvumelane nokusetshenziswa kwamathuluzi womoya wokulungisa, ububanzi bepayipi kanye ne-valve enqanyuliwe yepayipi lomoya elicindezelwe esiteshini somphakathi kungandiswa ngokufanele, isibonelo, i-DN25 inyuswe kumishini ye-DN50, kanye nejoyinti yepayipi ehambisana ne isiteshi somphakathi singabiwa ne-exhaust yepayipi lemishini; Ekufakweni okukhulu, imbobo yokuxhuma impahla evamile (UC) ingase ihlinzekwe ezintweni zokusebenza. Imbobo yokuxhuma kanye nevalvu yokukhipha umoya kuzotholakala engxenyeni engezansi nengaphezulu yempahla eqondile noma kuzo zombili iziphetho zobude bendawo yokusebenza evundlile ngokulandelana. Lapho ipayipi lempahla evamile lingangcoliswa ukugeleza koketshezi oluqhubekayo, amavalvu okuhlola kufanele abekwe ezansi nomfula ovamile wokunqamula amapayipi.

umbhoshongo

Gcina ingcindezi ye-steam condensing ku-condenser phezulu kombhoshongo ngangokunokwenzeka njengokucindezela phezulu kombhoshongo, ukwehla kokucindezela kwepayipi phezulu kombhoshongo kuze kube kuncane, ngaphandle kwe- izidingo ezikhethekile zokulawulwa kwenqubo, akukho valve yokusika ebekwe epayipini ukusuka phezulu kombhoshongo kuya ku-condenser. Ipayipi yokuxhuma phakathi kwe-reboiler (kuhlanganise ne-reboiler ephakathi) kanye nomzimba wombhoshongo akufanele ifakwe i-valve yokuvala, ngaphandle kwalawo adingekayo ekulawuleni inqubo noma ukuhlanza ngesikhathi sokusebenza kwedivayisi.

Lapho i-valve ifakwe kwipayipi yokuxhuma ye-thermal siphon reboiler kanye nomzimba wombhoshongo, i-valve yesango enobubanzi obufanayo nepayipi yokuxhuma izosetshenziswa. Ipuleti eliyimpumputhe elinesibalo esingu-8 lizofakwa phakathi kwe-valve ne-reboiler, futhi i-reboiler izohlonyiswa ngama-drain valves ayo, njengoba kuboniswe kuMfanekiso 2.0.5-1. I-single-pass thermal siphon reboiler kufanele ingeze ipayipi yokuxhuma phakathi kwe-inlet yempahla ye-reboiler kanye nembobo yokukhipha ngaphansi kombhoshongo futhi isethe i-valve yokusika, njengoba kuboniswe ku-Figure 2.0.5-2. Ububanzi be-valve kufanele okungenani bube yi-1/4 enkulu kunepayipi lokukhipha ngaphansi kombhoshongo.

I-FIG. 2.0.5-1 Gcina isethingi ye-valve eseceleni ye-siphon eshisayo

I-FIG. 2.0.5-2 Izilungiselelo zevalvu ye-one-pass reboiler

Iyini imbangela yokungagqwali kwe-valve?

I-valve iyimishini yokulawula evame ukusetshenziswa, kukhona i-valve evimbela ukubola kanye ne-valve engaguli, i-valve ivamise ukulawula ubukhulu besilinganiso sokugeleza kwe-liquid noma igesi nokushintsha, ukugqwala kwe-valve kungesinye sezizathu eziyinhloko zokwehluleka kwe-valve, kunezinhlobo eziningana zokugqwala noma imbangela ukugqwala, ngokuvamile zingahlukaniswa zibe izinhlobo eziyisithupha ukugqwala. Ukugqwala kuyindlela engokwemvelo nemoshayo yokufaka izinsimbi kuma-ore azo.

Ikhemikhali yokugqwala igcizelela ukugqwala okuyisisekelo kwe-M0M + ama-electron, lapho i-M0 iyinsimbi futhi i-M iyinsimbi e-positively ionic, inqobo nje uma insimbi (M0) igcina ama-electron, uhlala eyinsimbi. Uma kungenjalo izogqwala. Amandla abonakalayo Isikhathi esiningi amandla enyama namakhemikhali azosebenzisana ukwenza ivalvu ihluleke. Kunezinhlobo eziningi ezijwayelekile zokugqwala, ikakhulukazi ezidlulanayo. Indlela yokumelana nokugqwala kungenxa yokwakheka kwefilimu ewugqinsi evikelayo evikelayo endaweni yensimbi. Khona-ke izizathu zokuhluleka kokubola kwe-valve zibalwe ngezansi ukwenza isingeniso;

1, ukugqwala komgodi

Ukugqwala kwendawo noma umgodi kwenzeka lapho ifilimu evikelayo icekelwa phansi noma ungqimba lomkhiqizo wokugqwala lubola. I-membrane iqhuma ukuze yenze i-anode futhi ulwelwesi olunganqamuki noma umkhiqizo wokugqwala usebenza njenge-cathode, udala ngempumelelo isekethe evaliwe. Ezinye izinsimbi ezingenasici kulula ukuzifaka phambi kwama-ion e-chloride. Ukugqwala kwenzeka ezindaweni zensimbi noma ezingxenyeni ezimaholoholo ngoba azifani.

2, ukugqwala kwe-friction

Kusukela emandleni angokwenyama okuguga, insimbi incibilika ngokugqwala kokuvikela. Umphumela uncike kakhulu emandleni nesivinini. Ukudlidliza okuningi noma ukugoba kwensimbi kungaba nemiphumela efanayo. I-Cavitation iyindlela evamile yepompo yokugqwala, ukuqhekeka kwe-corrosion yokucindezeleka, ukucindezeleka okuphezulu kanye nomoya odlayo kuzodala ukugqwala kwensimbi. Lapho ingcindezi yokuqina endaweni yensimbi idlula indawo yokukhiqiza yensimbi ngaphansi komthwalo omile, ukugqwala kugxila endaweni yesenzo sokucindezeleka, futhi umphumela ubonisa ukugqwala kwendawo. Ekushintsheni ukugqwala kwensimbi kanye nokusungulwa kokugxilisana okukhulu kokucindezeleka kwezingxenye, ukugqwala okunjalo kungagwenywa ngokuqeda ukucindezeleka kwangaphambi kwesikhathi, noma ukukhethwa kwezinto ezifanele ze-alloy namasu okuklama. Ukukhathala kokugqwala Sivame ukuhlobanisa ingcindezi emile nokugqwala.

3, izinga lokushisa eliphezulu ukugqwala

Ukubikezela imiphumela ye-oxidation yokushisa okuphezulu, sidinga ukuhlola le datha: ukwakheka kwensimbi, ukwakheka komkhathi, izinga lokushisa kanye nesikhathi sokuchayeka. Kodwa izinsimbi eziningi ezikhanyayo (lezo ezilula kunama-oxide azo) zakha ungqimba lwe-oxide olungavikeleki oluba lugqinsi ngokuhamba kwesikhathi bese luyawa. Ezinye izinhlobo zokugqwala kokushisa okuphezulu zifaka i-vulcanization, i-carburization, njalonjalo.

4, ukugqwala kwegebe

Lokhu kwenzeka ezikhaleni ezivimba ukusakazeka komoyampilo, kudala izindawo zomoya-mpilo ophezulu neziphansi futhi zidale umehluko ekugxilweni kwesixazululo. Ikakhulukazi, amalunga noma ashiselwe amaphutha ngokuhlanganyela kungase kubonakale igebe ewumngcingo, ububanzi igebe (ngokuvamile 0.025 ~ 0.1mm) ngokwanele ukwenza isixazululo electrolyte singene igebe, insimbi nensimbi ngaphandle igebe ukwakha iseli galvanic wesifunda esifushane, kanye nokugqwala okuqinile kwendawo esikhaleni.

5, ukugqwala kagesi

Uma izinsimbi ezimbili ezihlukene zithintana futhi zivezwe oketshezini olubolayo nama-electrolyte, akha amaseli e-galvanic, okwamanje kubangela ucezu lwe-anodic ukuthi lugle futhi lwandise lwamanje. Ukugqwala kuvame ukwenziwa okwasendaweni eduze nendawo othintana naye. Ukunciphisa ukugqwala kungafinyelelwa ngokufaka izinsimbi ezihlukene.

6. Ukugqwala kwe-Intergranular

Ukugqwala kwe-Intergranular kwenzeka ngenxa yezizathu ezihlukahlukene. Umphumela uba ukucekelwa phansi kwempahla okucishe kufane okufanayo emingceleni yezinhlamvu zensimbi. I-Intergranular corrosion ye-austenitic stainless steel at 800 — 1500° F ingaphansi kwe-ejenti egqwalayo (427 — 816°C) ngaphandle kokuphathwa kahle kokushisa noma ukuzwela ukuthintana. Lesi simo singaqedwa ngokuqothula kusengaphambili nokucisha ku-2000°F (1093°C) kusetshenziswa insimbi engagqwali enekhabhoni ephansi (C-0.03 Max) noma i-niobium eqinile noma i-titanium.

Isikhathi sokuthumela: Jul-11-2022