Dab tsi yog qhov ua rau valve corrosion tsis ua haujlwm?

Txhawm rau hloov mus rau kev siv cov cuab yeej pneumatic rau kev saib xyuas, cov yeeb nkab txoj kab uas hla thiab txiav tawm valve ntawm compressed cua yeeb nkab hauv cov chaw nres tsheb pej xeem tuaj yeem tsim nyog, piv txwv li, DN25 yog nce mus rau DN50 cov khoom, thiab cov yeeb nkab sib koom ua ke nrog cov khoom siv pneumatic. chaw nres tsheb pej xeem tuaj yeem koom nrog cov pa tawm ntawm cov khoom siv yeeb nkab; Rau kev teeb tsa loj, cov khoom siv sib txuas sib txuas (UC) tuaj yeem muab rau ntawm cov khoom siv. Qhov chaw nres nkoj sib txuas thiab lub qhov cua valve yuav tsum nyob rau hauv qis thiab sab sauv ntawm cov cuab yeej ntsug lossis ob qho kawg ntawm qhov ntev ntawm cov khoom siv kab rov tav. Thaum cov khoom siv hauv cov kav dej yuav kis tau los ntawm cov txheej txheem dej rov qab, cov khoom siv yuav tsum tau muab tso rau hauv qab ntawm cov khoom siv cov yeeb nkab txiav tawm valve.

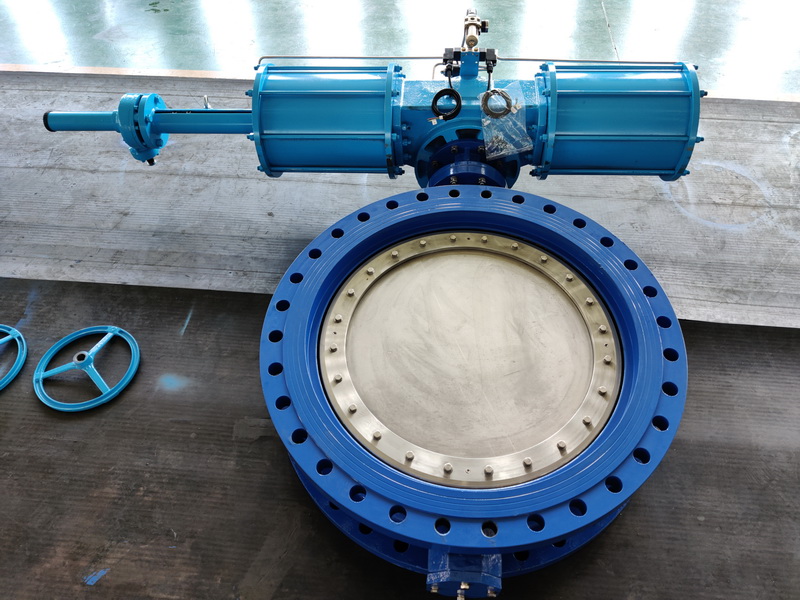

Kev sib txuas: Kev teeb tsa yooj yim ntawm lub valve

Cov txheej txheem tshuaj lom neeg muaj kev tshaj lij hauv kev tsim cov kev kub siab khib nyiab boiler thiab chav kaw lus, tuaj yeem xa mus rau lub hwj chim tswj

Cov kev cai cuam tshuam ntawm Ministry of Industry thiab Power Construction Bureau:

Cov kev cai rau kev tsim cov kav dej hauv cov kav dej Thermal (DLGJ 233-81)

Tshooj 7 ~ 7 1: Pg≥40 yeeb nkab tso dej thiab dej yuav tsum tau teem rau hauv series nrog ob lub valve.

Tshooj 7 ~ 8 1: Pg≥40 "rau lub tshuab pa ntawm lub raj xa dej, ob qhov nres valve yuav tsum tau teem rau hauv series.

Chav tsev ntawm kev tawm siab yog kg / cm2 ( rooj).

Thaum siv, thov xyuam xim rau cov kev cai ntawm *** version.

Rau hydrocarbons, tshuaj lom thiab teeb meem tshuaj thiab lwm yam ntaub ntawv thiab lwm yam txheej txheem cov ntaub ntawv txuas mus rau sab sauv thiab nyob rau hauv lub vent, vent yeeb nkab teem ob li qub li qub, tuaj yeem xa mus rau Table 2.0.3

Table 2.0.3 kub thiab siab tej yam kev mob rau dual li qub

Pej xeem cov ntaub ntawv chaw nres tsheb (public engineering chaw nres tsheb) Cov khoom siv pej xeem chaw nres tsheb (cov chaw nres tsheb ib ntus luv luv) nyob rau hauv cov tshuaj nroj tsuag tuaj yeem teeb tsa raws li thaj chaw uas npog thaj tsam li 15m, thaum lub chaw nres tsheb pej xeem sab nraum thaj chaw cog tuaj yeem teeb tsa raws li rau tus tsim xav tau. Qhov kev txiav tawm valve specification ntawm txhua qhov nruab nrab ntawm DN15 txog DN50 nyob ntawm tus yam ntxwv ntawm lub cuab yeej.

Cov li qub thiab cov pob qij txha ntawm cov ntaub ntawv pej xeem ntawm qhov chaw nres tsheb tuaj yeem ua rau tsis sib haum, thiab qhov kev txiav txim ntawm cov xov xwm hauv txhua lub chaw nres tsheb pej xeem yuav tsum ua kom zoo ib yam, txhawm rau kom tsis txhob nthuav dav ntawm kev sib tsoo ntawm qhov nruab nrab tsis raug thaum muaj xwm txheej ceev.

Cov kav dej ntawm cov chaw nres tsheb sab nraum zoov hauv cov chaw txias tuaj yeem ua tau raws li hauv qab no:

(1) Multi-layer thav duab: raws li cov pa yeeb nkab teeb tsa valve, txiav tawm ze rau hauv qab hauv av thiab teeb tsa kev sib koom ua ke sai, thaum siv dej los ntawm cov dej nyob ze ntawm qhov dej zoo. Yog tias siv cov kav dej ruaj khov thiab cov dej ntws tawm, lub valve yuav tsum nyob hauv qhov zoo.

(2) Hauv qhov chaw cia khoom lossis chaw thau khoom thiab tshem tawm lub platform, txoj haujlwm ntawm lub valve zoo tuaj yeem hloov kho kom zoo los ntawm kev sib tham nrog cov neeg siv dej thiab cov dej ntws, thiab cov dej xa dej tuaj yeem nyob hauv lub valve zoo.

(3) Kev txuag hluav taws xob nrog cov kav dej.

Txhawm rau hloov mus rau kev siv cov cuab yeej pneumatic rau kev saib xyuas, cov yeeb nkab txoj kab uas hla thiab txiav tawm valve ntawm compressed cua yeeb nkab hauv cov chaw nres tsheb pej xeem tuaj yeem tsim nyog, piv txwv li, DN25 yog nce mus rau DN50 cov khoom, thiab cov yeeb nkab sib koom ua ke nrog cov khoom siv pneumatic. chaw nres tsheb pej xeem tuaj yeem koom nrog cov pa tawm ntawm cov khoom siv yeeb nkab; Rau kev teeb tsa loj, cov khoom siv sib txuas sib txuas (UC) tuaj yeem muab rau ntawm cov khoom siv. Qhov chaw nres nkoj sib txuas thiab lub qhov cua valve yuav tsum nyob rau hauv qis thiab sab sauv ntawm cov cuab yeej ntsug lossis ob qho kawg ntawm qhov ntev ntawm cov khoom siv kab rov tav. Thaum cov khoom siv hauv cov kav dej yuav kis tau los ntawm cov txheej txheem dej rov qab, cov khoom siv yuav tsum tau muab tso rau hauv qab ntawm cov khoom siv cov yeeb nkab txiav tawm valve.

pej thuam

Khaws lub condensing chav siab nyob rau hauv lub condenser nyob rau sab saum toj ntawm lub pej thuam kom ntau li ntau tau raws li tib yam li lub siab nyob rau sab saum toj ntawm lub pej thuam, lub siab poob ntawm cov yeeb nkab nyob rau sab saum toj ntawm lub pej thuam mus rau qhov tsawg kawg nkaus, tshwj tsis yog rau lub siab. tshwj xeeb cov kev xav tau ntawm cov txheej txheem tswj, tsis muaj kev txiav tawm valve yog teem rau ntawm cov yeeb nkab los ntawm sab saum toj ntawm tus pej thuam mus rau lub condenser. Cov yeeb nkab txuas nruab nrab ntawm lub reboiler (xws li lub nruab nrab reboiler) thiab cov pej thuam lub cev yuav tsum tsis txhob nruab nrog lub tshuab txiav tawm, tshwj tsis yog rau cov uas yuav tsum tau ua rau kev tswj xyuas lossis tu thaum lub sijhawm ua haujlwm ntawm lub cuab yeej.

Thaum lub valve raug ntsia rau ntawm cov yeeb nkab txuas ntawm lub thermal siphon reboiler thiab ntauwd lub cev, lub rooj vag valve nrog tib txoj kab uas hla raws li cov yeeb nkab txuas yuav tsum tau siv. Ib daim duab 8-daim duab dig muag yuav tsum tau nruab nruab nrab ntawm lub valve thiab lub reboiler, thiab lub reboiler yuav tsum tau nruab nrog lawv cov dej ntws li qub, raws li pom hauv daim duab 2.0.5-1. Ib qho dhau ntawm thermal siphon reboiler yuav tsum ntxiv cov yeeb nkab sib txuas ntawm cov khoom nkag ntawm lub reboiler thiab qhov chaw nres nkoj tawm hauv qab ntawm tus pej thuam thiab teeb tsa lub valve txiav, raws li qhia hauv daim duab 2.0.5-2. Txoj kab uas hla ntawm lub valve yuav tsum yog tsawg kawg yog 1/4 loj dua li cov yeeb nkab tawm hauv qab ntawm tus pej thuam

FIG. 2.0.5-1 Spare thermal siphon reboiler txheej txheem sab valve chaw

FIG. 2.0.5-2 one-pass reboiler valve Chaw

Dab tsi yog qhov ua rau lub valve tsis ua haujlwm corrosion?

Valve feem ntau siv cov cuab yeej tswj, muaj cov khoom siv tiv thaiv corrosion thiab tsis yog-anticorrosive valve, valve feem ntau tswj qhov loj ntawm cov kua lossis roj ntws thiab hloov, valve corrosion yog ib qho laj thawj tseem ceeb rau valve tsis ua haujlwm, muaj ntau hom kev xeb lossis qhov ua rau corrosion, feem ntau tuaj yeem muab faib ua rau rau hom corrosion. Corrosion yog lub ntuj thiab nkig txoj kev uas tau txais hlau rau hauv lawv cov ore.

Lub chemistry ntawm corrosion hais txog qhov yooj yim corrosion tshwm sim ntawm M0M + electrons, qhov twg M0 yog hlau thiab M yog ib tug zoo ionic hlau, tsuav yog cov hlau (M0) khaws electrons, nws tseem yog hlau. Txwv tsis pub nws yuav corrode. Lub cev rog Feem ntau ntawm lub sijhawm lub cev thiab tshuaj lom neeg yuav ua haujlwm ua ke kom lub valve tsis ua haujlwm. Muaj ntau ntau hom kev xeb, feem ntau sib tshooj. Cov txheej txheem tiv thaiv corrosion yog vim yog tsim cov yeeb yaj kiab tuab tiv thaiv corrosion ntawm cov hlau nto. Tom qab ntawd cov laj thawj rau lub valve corrosion tsis ua haujlwm tau teev tseg hauv qab no los ua kev taw qhia;

1, corrosion kuj

Hauv zos corrosion los yog pitting tshwm sim thaum cov yeeb yaj kiab tiv thaiv raug puas los yog cov khoom lag luam corrosion yog decomposed. Lub membrane ruptures los tsim ib qho anode thiab cov khoom tsis sib haum xeeb lossis cov khoom siv corrosion ua raws li cov cathode, tsim kom muaj lub kaw lus kaw. Qee cov hlau tsis muaj steel yog yooj yim rau pitting nyob rau hauv lub xub ntiag ntawm chloride ions. Corrosion tshwm sim ntawm cov hlau los yog qhov chaw ntxhib vim tias cov no tsis yog homogeneous.

2, kev sib txhuam corrosion

Los ntawm lub cev rog ntawm hnav thiab tsim kua muag, cov hlau yog yaj los ntawm kev tiv thaiv corrosion. Cov nyhuv yog nyob ntawm lub zog thiab ceev. Kev vibration ntau dhau los yog khoov ntawm cov hlau tuaj yeem muaj cov txiaj ntsig zoo sib xws. Cavitation yog ib hom ntawm corrosion twj tso kua mis, kev nyuaj siab corrosion cracking, siab tensile kev nyuaj siab thiab corrosive cua yuav ua rau hlau corrosion. Thaum lub tensile kev nyuaj siab ntawm cov hlau nto tshaj qhov yield point ntawm cov hlau nyob rau hauv zoo li qub load, corrosion concentrates nyob rau hauv lub cheeb tsam ntawm kev nyuaj siab, thiab qhov tshwm sim qhia ib tug hauv zos corrosion. Nyob rau hauv alternating hlau corrosion thiab tsim kom muaj kev ntxhov siab concentration ntawm qhov chaw, xws li corrosion yuav zam tau los ntawm kev ntxhov siab thaum ntxov annealing, los yog xaiv cov ntaub ntawv tsim nyog alloy thiab tsim schemes. Corrosion qaug zog Peb feem ntau koom nrog kev ntxhov siab zoo nrog corrosion.

3, kub kub corrosion

Txhawm rau kwv yees qhov cuam tshuam ntawm qhov kub thiab txias oxidation, peb yuav tsum tau tshuaj xyuas cov ntaub ntawv no: hlau muaj pes tsawg leeg, huab cua muaj pes tsawg leeg, kub thiab lub sijhawm raug. Tab sis feem ntau cov hlau teeb (cov uas sib zog dua lawv cov oxides) tsim ib txheej uas tsis muaj kev tiv thaiv oxide uas tau thicker lub sij hawm thiab ntog. Lwm cov ntaub ntawv ntawm kev kub siab corrosion muaj xws li vulcanization, carburization, thiab lwm yam.

4, qhov sib txawv corrosion

Qhov no tshwm sim hauv qhov khoob uas thaiv qhov diffusion ntawm oxygen, tsim cov cheeb tsam siab thiab qis oxygen thiab tsim kom muaj qhov sib txawv hauv kev daws teeb meem. Tshwj xeeb, cov pob qij txha los yog welded sib koom ua ke tsis xws luag yuav tshwm sim nqaim qhov sib txawv, qhov dav dav (feem ntau hauv 0.025 ~ 0.1mm) txaus los ua cov tshuaj electrolyte rau hauv qhov sib txawv, cov hlau thiab cov hlau sab nraud ntawm qhov sib txawv los tsim ib qho luv luv Circuit Court galvanic cell, thiab muaj zog hauv zos corrosion nyob rau hauv qhov sib txawv.

5, hluav taws xob corrosion

Thaum ob lub hlau sib txawv nyob rau hauv kev sib cuag thiab raug corrosive kua thiab electrolytes, tsim galvanic hlwb, tam sim no ua rau cov anodic corrode thiab ua rau kom cov tam sim no. Corrosion feem ntau yog nyob ze ntawm qhov chaw sib cuag. Kev txo qis ntawm corrosion tuaj yeem ua tiav los ntawm plating cov hlau tsis sib xws.

6. Intergranular corrosion

Intergranular corrosion tshwm sim rau ntau yam laj thawj. Qhov tshwm sim yog yuav luag zoo tib yam cov cuab yeej cuab tam kev puas tsuaj raws li cov hlau lis ciam teb. Intergranular corrosion ntawm austenitic stainless hlau ntawm 800 - 1500 ° F yog raug rau ntau tus neeg ua haujlwm corrosive (427 - 816 ° C) yam tsis muaj kev kho cua sov lossis kev sib cuag. Qhov xwm txheej no tuaj yeem raug tshem tawm los ntawm kev ua ntej annealing thiab quenching ntawm 2000 ° F (1093 ° C) siv cov pa roj carbon tsawg (C-0.03 Max) lossis niobium lossis titanium stabilized.

Post lub sij hawm: Lub Xya hli ntuj-11-2022