Iimfuno ngokubanzi zofakelo, ukusetyenziswa kunye nokugcinwa kweevalvu zemveliso yoshishino Umda wemveliso yeevalvu zovavanyo loxinzelelo kunye nemimiselo yovavanyo yaziswa ngokweenkcukacha.

Ekufakeni i-valve ye-flange, kuyimfuneko ukubeka ingqalelo kwi-symmetry kunye ne-uniform tightening nut. I-valve ye-valve kunye ne-flange ye-pipe kufuneka ihambelane, ingabikho isebenzayo, ukukhusela i-valve ibangele uxinzelelo oluninzi, kwizinto ezingezona zetsimbi kunye namandla aphantsi oxinzelelo lwe-valve, ingqalelo ekhethekileyo kufuneka ihlawulwe. Umdibaniso odibeneyo uya kwakhiwa ngokuhambelana nendlela ye-welding ehambelana neemfuno zokuvavanya inkqubo ye-welding, ukwenzela ukukhusela ukungcola okufana ne-solder jam ekungeneni kwipayipi. Emva kwe-welding yombane yee-valve kunye nemibhobho, uvavanyo olungonakaliyo lwe-welding luya kwenziwa ngokweemfuno. Iivalvu ezinomatshini wokuqhuba, izixhobo zombane, ukunikezelwa kwegesi kunye ne-hydraulic tubing kufuneka zixhunywe ngokwendlela yocingo okanye umzobo wombhobho wemiyalelo, kwaye ukuchaneka kwe-wiring kufuneka kunqunywe ngaphambi kokufikelela.

Uxhulumaniso oluphezulu: Iimfuno ngokubanzi zofakelo, ukusetyenziswa kunye nokugcinwa kweevalvu zemveliso yoshishino (I)

4.2.2 Ezothutho

Xa uphakamisa i-valve, intambo akufanele iboshwe kwi-shaft enkulu okanye isihlalo, kodwa kufuneka iboshwe kwi-valve bolt okanye i-flange. I-spindle okanye i-rocker akufanele isetyenziswe njengesiphatho xa uthuthwa.

4.2.3 Uqhagamshelwano

4.2.3.1 Khetha imowudi yoqhagamshelo yecala lombhobho ngokwendlela yoqhagamshelo lwevalvu. I-flange yombhobho kunye ne-screw iya kufana neenkcukacha zevalve.

4.2.3.2 Umbhobho oqhagamshelwe kwivalvu uya kucocwa ukunqanda isikhonkwane sentsimbi, isanti ecolekileyo, isiva sewelding kunye nolunye ukungcola ekutshabalaliseni ivalve protrusion.

4.2.3.3 Ufakelo lwevalve yokudibanisa iflange, kufuneka kuqala utywine ukupakisha (umsonto kunye neoyile yelothe okanye iteyiphu yePTFE) kumsonto wombhobho, ukuthintela ukuqokelelana kwememori yevalve, ukonakalisa ukujikeleza kwempahla.

4.2.3.4 Ufakelo lwe-Flange Valve, nikela ingqalelo kwi-symmetry kunye ne-uniform nut tightening. I-valve ye-valve kunye ne-flange ye-pipe kufuneka ihambelane, ingabikho isebenzayo, ukukhusela i-valve ibangele uxinzelelo oluninzi, kwizinto ezingezona zetsimbi kunye namandla aphantsi oxinzelelo lwe-valve, ingqalelo ekhethekileyo kufuneka ihlawulwe.

4.2.3.5 Umdibaniso odibeneyo uya kwakhiwa ngokuhambelana nendlela ye-welding ehambelana neemfuno zovavanyo lwenkqubo ye-welding ukukhusela ukungcola okufana ne-solder jam ekungeneni kwipayipi. Emva kwe-welding yombane yee-valve kunye nemibhobho, uvavanyo olungonakaliyo lwe-welding luya kwenziwa ngokweemfuno.

4.2.4 Iigaskets

I-Gasket kufuneka ikhethwe ngokohlobo lwe-flange, inqanaba loxinzelelo lokusebenza, ubushushu, izinto eziphathekayo kunye nezinye iimeko.

4.2.5 Ukudityaniswa kwendlela yokuqhuba

Iivalvu ezinomatshini wokuqhuba, izixhobo zombane, ukunikezelwa kwegesi kunye ne-hydraulic tubing kufuneka zixhunywe ngokwendlela yocingo okanye umzobo wombhobho wemiyalelo, kwaye ukuchaneka kwe-wiring kufuneka kunqunywe ngaphambi kokufikelela.

4.2.6i ilungisiwe

Isiseko njenge-valve yokuxhasa, indibano esisiseko kufuneka iqine.

4.2.7 IiMfuno eziZodwa

4.2.7.1 Iivalvu ezinemigangatho yokugquma ubushushu yangaphandle kunye nemigangatho yokugquma okubandayo ziya kwakhiwa ngomaleko okhuselayo phambi kokuba kungene imathiriyeli.

4.2.7.2 Xa ufaka ivalve yokhuseleko, nikela ingqalelo kwindawo yogutyulo kwaye uyithintele ukuba ingajongani nabasebenzi abasebenzayo.

4.3 Uhlengahlengiso Emva koFakelo

4.3.1 Ukulungiselela uLungiso

Ngaphambi kokumiselwa kwenkqubo, ivalve kufuneka ivavanywe ngombhobho ngaphambi kokuba ilungiswe. Umfowunelwa kufuneka ajongwe ukuvuza. Iivalvu ezizodwa ziya kuchazwa.

4.3.2 Uvavanyo lokusebenza kwevalvu yombane

Amanyathelo okulawula kwimeko yolawulo lwendawo, ivalve yezandla kwindawo esembindini, qhuba umsebenzi wovavanyo lwemoto, ukufikelela kwiqhosha lokuvula okanye lokuvala nqumama okwethutyana, jonga ukuba indlela yokutshintsha yevalve yombane iyahambelana nophawu lokutshintsha amandla kunye nevalve ngokwayo. , kungenjalo kufuneka uqhube ukuhlolwa komgca womlilo ongathathi hlangothi okanye utshintsho lweentambo.

4.3.3 Ukumiselwa kweTshintsho lokuhamba

4.3.3.1 Utshintsho oluqhelekileyo lokuhamba lusetwa phambi kokuba uphume efektri, kwaye akukho luhlenga-hlengiso lufunekayo.

4.3.3.2 Ukuma kweSetingi kwi-Adjustment switch. Ivalve ye-Manual iindawo ezibaluleke kakhulu, kunye nokujikeleza i-1 ~ 2 laps, kunye ne-screwdriver kunye nezinye izixhobo zokulungelelanisa i-stroke switsha iindawo ezibalulekileyo, ukutshintshwa kwe-stroke nje kwi-posture, kunye ne-multimeter ukufumanisa iswitshi ye-stroke, isignali yedatha yokuthumela ngaphandle kufuneka ifaneleke.

4.3.3.3 Ukulungelelanisa isethingi yokubeka iyafana nale ingentla.

4.3.4 Igalelo lemiyalelo yolawulo yeevalvu zombane kunye ne-electromagnetic induction valves kufuneka zihambelane nemigaqo yendlela yokuqhuba.

4.3.5 Uxinzelelo olubi lokusebenza kweevalvu zepneumatic kunye nehydraulic kufuneka zihambelane nemigaqo yendlela yokuqhuba.

4.3.6 Iivalvu ziya kudityaniswa kunye nesoftware yenkqubo ukujonga isenzo kunye nomsebenzi.

5 Ukusetyenziswa

5.1 IiMfuno ngokuBanzi

5.1.1 Isicelo sevalvu siya kuqhutywa ngokuhambelana nencwadana yokusebenza kwaye asiyi kudlula usetyenziso lweeparamitha zesakhiwo.

5.1.2 Abanini-zithuthi kufuneka balawule imigaqo esisiseko yokusebenza kwevalvu ngoqeqesho lwaphambi kokuya emsebenzini. Kuphephe ukwahlula ivalve, ukuvala ngendlela engeyiyo, ukuvuza, ukuvuza. Abaqhubi kufuneka babambe ngokucacileyo ukusebenza kwevalve nganye kunye nendawo yayo kumbhobho wenkqubo ukunqanda ukusetyenziswa kakubi.

5.1.3 I-valve yokutshintsha amandla ayifanelekanga kwi-valve ye-throttle, iindawo zokuvula kunye nokuvala akufanele zibe kwindawo ephakathi ixesha elide. Njengevalve yokumisa, ivalve yokumisa, ivalve yesango, ivalve yeplagi kunye nezinye iivalve zokuqhawula.

5.2 Ukusebenza kwevalvu ngesandla

5.2.1 Xa iswitshi yamandla evalve isetyenziswa, kuyimfuneko ukunikela ingqalelo kwicala lokutshintsha kwevalve. Ngokubanzi, i-shaft engundoqo okanye ivalve ye-rocker ivulwa ngokunxamnye newotshi kwaye ivalve ivalwe ngokwewotshi.

5.2.2 Ukusebenza ngesandla kwevalve, amandla kufuneka abe symmetrical, ukudibana kubambekile, kufuneka kujongwe isizathu ngexesha. Ngokubanzi abanakuthembela kumandla emali okanye ukusebenza kwe-wrench, ukuphepha amandla agqithisileyo, umonakalo kumphezulu kunye nezinye iindawo.

5.2.3 Xa kuvulwa ivalve yomphunga kunye nomphunga-ulwelo olunamanqanaba amabini, iya kuvulwa ngokucothayo ukususa i-condensate kumbhobho kwaye kuthintelwe ukuntlitheka kwamanzi.

5.2.4 Kwiivalvu ezisikiweyo, iivalve ezisikiweyo kunye neevalve ezinedayamitha enkulu yokungena, xa uvula, ivalve yokungena kufuneka ivulwe kuqala, ize ke ivuleke kancinane. Xa uvala i-valve, i-valve yokungena kufuneka ivalwe kuqala, kwaye i-valve engundoqo kufuneka ivalwe ngokukhawuleza.

5.3 Ukusebenza ngokuzeleyo kwevalvu

5.3.1 Isivalo somphunga, kuqala sebenzisa ivelufa yokudlula umbhobho ukucima i-condensate, ukuba kukho umphunga cima indlela yokudlula.

5.3.2 Iivalvu ziya kujongwa rhoqo.

5.3.3 Ukulungelelanisa i-valve ngokweemfuno zemeko yokusebenza, khetha iiparameters zohlengahlengiso ezifanelekileyo.

5.4 Eminye imisebenzi yokuhombisa umnyango

5.4.1 Kwiivalvu ezixhomekeke kumbane, i-electromagnetic induction, ipneumatic kunye nehydraulic valves kunye nezinye izixhobo ukuvula nokuvala, ukusebenza okugqibeleleyo okukude ngepaneli yesixhobo, iswitshi yombane, njl. njl. ivalve, baqonde ukusebenza iinkcukacha zobugcisa, kwaye ube nako ukwenza izisombululo zikaxakeka xa kukho iingozi.

5.4.2 Ivalve yombane Kuyimfuneko ukuthathela ingqalelo ukuhambelana kwesitayile kunye nemoto ekusebenzeni kwevalvu, ekufuneka ingagqithisi kuluhlu olusebenzayo.

5.4.3 Xa i-valve isebenza, ngokuqhelekileyo ayivumelekanga ukukhulula uxinzelelo kunye nokuqhaqha okanye ukugcwalisa izinto zokuzalisa.

5.4.4 Ukusebenza ngokuqhubekayo okuphezulu kunye nokuphantsi kweqondo lokushisa eliphakathi, abasebenzi abasebenza ngokukodwa kwisidingo sokunikela ingqalelo kukhuseleko lokhuseleko kunye nokhuseleko.

6 Isondlo

6.1 Ivalve iya kugcinwa kwigumbi elomileyo lokungenisa umoya, kwaye amacala omabini omjelo aya kuvaleka.

6.2 Iivalvu kugcino lwexesha elide ziya kugcinwa rhoqo, inkunkuma iya kupheliswa, kwaye iarhente yothintelo lomhlwa iya kusetyenziswa kwindawo yokuvelisa kunye nokulungiswa.

6.3 Ungayisebenzisi ivalve ixesha elide. Ukuba kunokwenzeka kakhulu, isikhundla kufuneka siqhutywe rhoqo ukuze kuqinisekiswe ukunyaniseka komsebenzi wayo.

6.4 Ukugcina oku kulandelayo ngamaxesha athile:

6.4.1 Iqondo lokukrazula kwesitulo sevalvu kunye ne-stem nut, kunye nokukhupha ngexesha elifanelekileyo.

6.4.2 Khangela ukuba isiphambuka sevalve sikhululekile kwaye silungise kwangethuba.

6.4.3 Ingaba imathiriyeli yokuzalisa iphelelwe lixesha kwaye ayisebenzi? Ukuba yonakele, kufuneka itshintshwe rhoqo. Ibhokisi yokupakisha ivalve ayifanelekanga ukucinezela ngokuqinileyo, kwaye kungcono ukuba ijoyinti yomkhono ingavuzi kwaye isihlalo sinokujikeleza ngokubonakalayo.

6.4.4 Qwalasela ukuguga okanye ukutshintshwa kwendawo ekumi kuyo isitshixo sombane kunye neqondo lokuguga komphezulu waso ovele phezulu. Kwaye ulungise kwangethuba umsesane wetywina wokubekwa endaweni.

6.5 Tyala ivalve

6.5.1 Isixa esifanelekileyo segrisi yokuthambisa ekhuthazwa kakhulu iya kuthi itofwe esitulweni okanye kwisitulo esitywiniweyo ngexesha elifanelekileyo ngokuhambelana nemiyalelo yokusetyenziswa.

6.5.2 Ukuze kuqinisekiswe eyona mpembelelo yegrisi yevalvu, ngamanye amaxesha kuyimfuneko ukuvula nokuvala ivalve, kwenziwe uhlolo lokhuseleko kweyona mpembelelo ye-oyile yokuthambisa, kwaye uqinisekise ukuba umphezulu womgangatho wokuvula nokuvalwa kwevalve. igudile.

6.5.3 Nika ingqalelo indawo yokutshintsha ivalvu ngexesha lokutofa igrisi. Ukuba kuyimfuneko, unyango lwamanzi amdaka kunye noxinzelelo lwengcinezelo kufuneka luqhutywe kuqala.

6.5.4 Emva kokutofa amafutha, qiniseka ukuba uyayitywina indawo yokutofa amafutha. Thintela intsalela ekungeneni okanye lipid inaliti yokuphuma lipid air oxidation, itywina ukucima igrisi antirust, ukuthintela umhlwa.

6.6 Xa ubushushu bungaphantsi kwe-0℃, kuyimfuneko ukunikela ingqalelo ekuthinteleni okubandayo kwiivalvu ezingasetyenziswayo, kwaye ngokukhawuleza uvule iplagi yocingo esezantsi yevalve ukukhupha amanzi ajikisiweyo ngaphakathi. Kwiivalvu ezingenakukhutshwa kwaye ziphazamise umsebenzi ochaphazelekayo, amanyathelo okukhusela kufuneka athathwe.

6.7 Ngexesha lolondolozo lwevalvu, kufuneka kuqwalaselwe ulondolozo lwemihla ngemihla lwee-activators kunye nezixhobo zothumelo. Ukucoca kuya kwenziwa ngokwemiyalelo yee-actuators. Ngokukodwa, i-seapage yamanzi ye-actuator kufuneka igwenywe ukukhusela ukubola kwamacandelo omatshini wesakhiwo sangaphakathi okanye ukucoca okubandayo ebusika.

6.8 Xa ivalve ivuza, kuyimfuneko ukumisela indawo evuzayo kunye nesizathu ngexesha kunye nokusombulula ingxaki ehambelanayo. Ngokubanzi, kukho iindidi ezimbini zokuvuza kunye nokuvuza. I-exposure yahlulwe ngokuzalisa ukuvuza kwezinto kunye ne-valve enye yokuhamba, ukuvuza kwepleyiti yesiphaluka se-oyile okanye i-lining yokuvuza kwezinto eziluhlaza ngokwesakhiwo sayo sangaphandle.

6.9 Iivalvu ezineemfuno ezizodwa ziya kugcinwa ngokwemiyalelo yokugcinwa kwazo kwesicelo.

(1) [Ulwazi olusisiseko lwe-Valve Fittings Ukwenziwa kwenethiwekhi kwilizwe lethu] Lo mgangatho uchaza imiqathango yovavanyo loxinzelelo, iimeko ezifanelekileyo, imimiselo, iindlela zokuvavanya kunye nenkqubo kunye nezibonelelo zeziphumo zovavanyo kwiivalvu zemathiriyeli yesinyithi. Uvavanyo loxinzelelo olushushu lwendlu yevalve yonke, eqhagamshelwe kwipleyiti yeoli kunye nesivalo sevalve. Injongo kukuvavanya umthamo wokuthwala, amandla oxinzelelo kunye noxinaniso lwezindlu zevalvu kunye nazo zonke izindlu ezibandakanya uqhagamshelwano olusisigxina kunye nolumileyo. uvavanyo lobushushu lolwelo Ubushushu bento ecinezelekileyo okanye igesi esetyenziselwa ukuvavanya uxinzelelo lwevalvu.

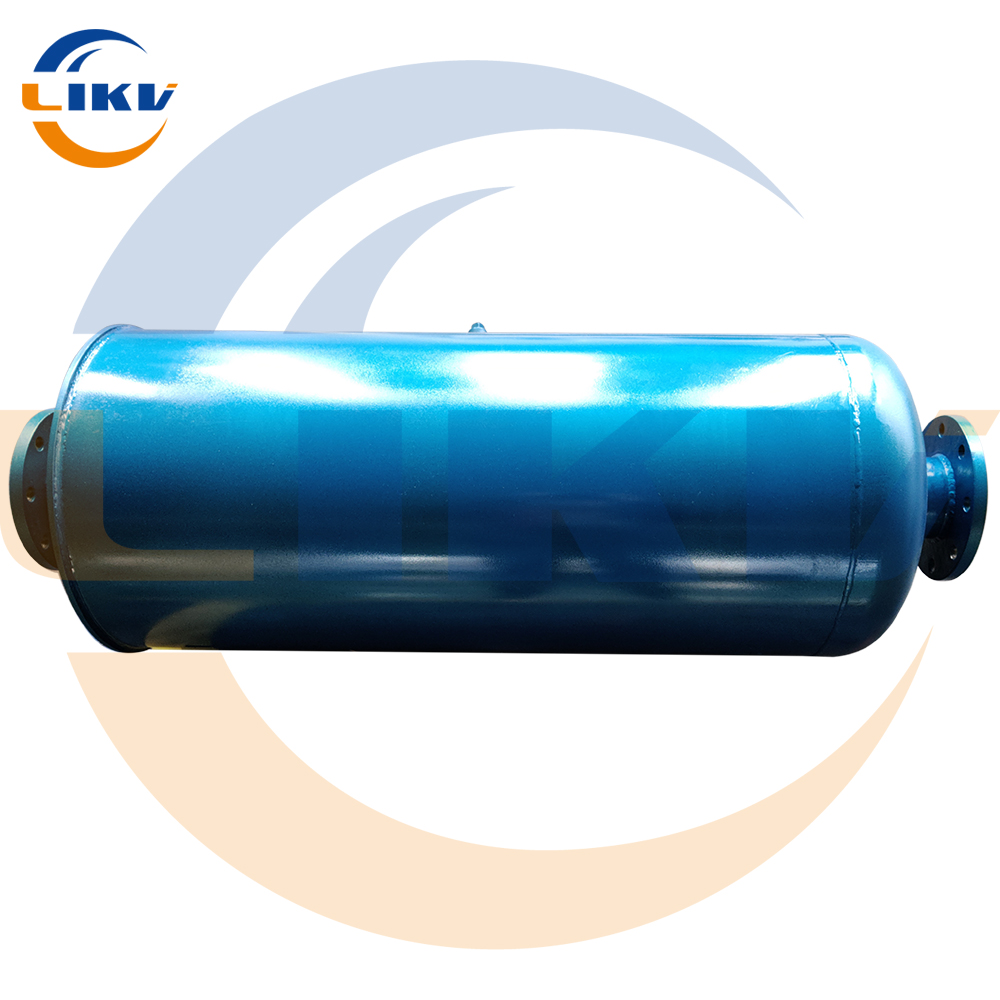

Uvavanyo loxinzelelo lwevalvu yeshishini

udidi

Lo mgangatho wesigama sovavanyo loxinzelelo lwentsimbi yesigama, uvavanyo loxinzelelo loxinzelelo ulwazi, imimiselo yovavanyo loxinzelelo, iindlela zovavanyo kunye neenkqubo kunye neziphumo zovavanyo.

Olu phawu lusebenza kwiivalvu zesinyithi zeshishini. Le ngcaciso iya kusetyenziswa ngokubambisana nomgangatho wokuphunyezwa kwemveliso yeevalvu.

Olu luhlu lunokusetyenziswa ngokubanzi kwezinye iindidi zeevalvu emva kokuvunywa ngamaqela omabini.

Ixesha lokuposa: Apr-25-2023