Ukukhethwa kweevalvu zesango kwinkqubo yokunikezelwa kwamanzi kunye nokwakhiwa kwe-drainage

Ivalve yesango esetyenziswa ixesha elide, ngaba uyazi ukuba ungaqinisekisa njani ukuqina kwevalve yesango? Lawula ngokungqongqo inkqubo yokuthenga kwaye wenze imibuzo ngokucophelela. Rekhoda ukusetyenziswa kofakelo lwemibhobho kunye nemibhobho yazo zonke iibhetshi kwaye uyibuyisele ngokukhawuleza xa kukho nawaphi na amathandabuzo afunyenweyo. Kwizixhobo zepayipi zePPR, i-ductility yesisombululo ukuthatha amanyathelo okuthintela. Iindlela zobugcisa zingasetyenziselwa: ukubekwa kwemibhobho engangcwatywa ngokuthe ngqo, kufuneka kuthathelwe ingqalelo isisombululo sombhobho wokwandiswa kwe-thermal kunye ne-contract contraction deformation yeendlela zobugcisa. I-ductility yombhobho kufuneka ibuyekezwe ngengalo esongwayo yombhobho kangangoko kunokwenzeka; Xa imibhobho ingasetyenziswa njengembuyekezo yendalo, ezinye iindlela zembuyekezo kufuneka zisetyenziswe.

Unikezelo lwamanzi kunye nenkqubo yokwakhiwa kobunjineli bemijelo ehlala idibana nokuvaleka kombhobho wokuhambisa amanzi, ukuvuza kombhobho, ukhetho lwevalvu yesango kunye nesixhobo, ingxolo kunye neminye imibuzo, uthungelwano lomntu wonke ukuba ahlalutye izinto zalo mbuzo, kwaye abeke ngokucacileyo phambili iindlela zokuthintela kunye nezisombululo.

1. Ukuphepha kunye nesisombululo sombuzo wokuvaleka kwemibhobho yokuhambisa amanzi

Izinto: ukuvaleka kombhobho wokuhambisa amanzi kwigumbi yimpazamo esemgangathweni eqhelekileyo ekwakhiweni kwesixhobo sokwakha, nto leyo ingumbuzo omdala ukuba isixhobo sombhobho kunye nentsebenziswano yobunjineli boluntu ayinakusombulula. Kwinkqubo yokwakhiwa komnqamlezo wobunjineli boluntu kunye nofakelo, kukho iimeko ezininzi zokuvaleka kwemibhobho, ngakumbi ukuvulwa kombhobho wokuhambisa kunye nedreyini yomgangatho wokukhupha ivumba kwigumbi elicocekileyo. Nangona umbhobho ufakwe kwaye umbhobho wesebe uvaliwe nge-samente slurry, idla ngokuvulwa ngabanye ukuba basebenze njengendawo yokucoca amanzi angcolileyo kwikhonkrithi kunye nomgangatho osicaba. Abanye bade bawe ngamaplanga, isanti kunye negrabile, inkunkuma, udaka lwesamente njalo njalo ukusuka kumbhobho wokungenisa umoya ophahleni kunye ne-emele yamanzi emvula, okubangela ukuvaleka kwemibhobho. Ukusetyenziswa okulula kokuhanjiswa kwabasebenzi, itshizili enzima kumhlaba wekhonkrithi, kusetyenzwa kwakhona ukurhoxisa umbhobho ukusuka kwisixhobo sokuqala, emva koko zombini ukusetyenziswa kwabasebenzi kunye nezinto, kwaye zonakalise ixesha lokwakha. Eminye imibhobho yokuhambisa amanzi inesithintelo esithile kwisigxina sombhobho, ongenakukwazi ukunyangwa ngexesha kwinkqubo yovavanyo loxinzelelo kunye nokuhanjiswa kwamanzi. Emva kotyalo-mali lwe-capital, ngokuqinisekileyo kuya kubonisa ukuvalelwa kombhobho kunye nokulimaza isicelo somthengi.

Ukuthintela kunye nesisombululo: ukwenzela ukuthintela ukuvaleka kombhobho kwinkqubo yokwakhiwa komnqamlezo, ngaphezu kokusetyenziswa kwentliziyo ngokusebenzisa umbhobho wombhobho, ukususa ukungcola, ngokufanelekileyo ngokwemigangatho echanekileyo yokusetyenziswa kweendawo zombhobho wokuhambisa amanzi; Umgca wesixhobo, kufuneka uqinisekise ukuthambeka kunye nocwangciso olupheleleyo kunye neemfuno ezisemgangathweni, kunye nokuwela idreyini ngokwamkela indlela yetywina elidityanisiweyo elixubeneyo, qiniseka ukuba uthathe njengoko kubonisiwe kumanyathelo obugcisa ahlukeneyo okuthintela ukutsalwa kwemibhobho: ngenxa yesakhiwo sokwakha. izinto, xa igama nge ab kumbhobho riser, kufuneka ngokweemfuno iinkcukacha, iseti phezulu ityhubhu b igama umbuzo umlomo kulula ukulungisa; Xa kungekho mfuneko kwisicwangciso esipheleleyo, i-port yokucoca kufuneka ifakwe kumbhobho we-waste cross cross kunye ne-2 okanye ngaphezulu kwe-2 izixhobo ze-excreta okanye i-3 okanye ngaphezulu kwe-3 izixhobo zokucoca ngokuhambelana nokwakhiwa kobunjineli kunye nemigangatho yokuhlola. I-port yombuzo okanye i-port yokucoca kufuneka ibekwe kumbhobho wokuwela amanzi amdaka kunye nee-degrees ezingaphantsi kwe-135 kwikona. Isixhobo sombhobho wokuhambisa amanzi wangcwatywa okwexeshana awukhutshwanga ityhubhu kunye nombhobho othe nkqo, umbhobho emlonyeni wesikhuphukeli umbuzo ofakwe ipleyiti yokugqibela okanye enye indlela yokuvalela entolongweni, kwaye ngoko nangoko wenze isixhobo sokunyuka sinxibe 2 umngxuma wekhonkrithi emgangathweni, emva kokuvunywa kwisinyusi esisisigxina, ukurhoxiswa okwethutyana. inkxaso, eli sebe kufuneka lizame ukunciphisa ubunjineli boluntu njengokungena nokuphuma kwamanzi amdaka okwethutyana. Kuyilo lobunjineli bobunjineli umhombiso emva kokuphela kwengcambu, phambi konikezelo lwamanzi kunye nemisele ecacileyo isixhobo riser isicelo, kuba umaleko ezantsi kunye ezimbini ngaphezu kombhobho umbuzo uvavanyo lokunkcenkceshela, uqinisekise ukuba icandelo umbhobho ngamnye unxibelelana, uze usebenzise. Umkhono othe ngqo (umbhobho) uya kubuza umbhobho womlomo kunye nomzantsi we-docking yokukhupha umbhobho.

2, ukuphepha kunye nesisombululo sombuzo wokuvuza kwemibhobho

Umbuzo wokuvuza kombhobho kubonelelo lwamanzi kunye nolwakhiwo lobunjineli bombhobho wokuhambisa amanzi luthandabuza oluxhaphakileyo, imiba yalo mbuzo ingaphezulu, ukuthintelwa kunye nokulahlwa kwalo mbuzo likhonkco elibalulekileyo lenkxalabo yonikezelo lwamanzi kunye nokwakhiwa kobunjineli bokuhambisa amanzi, iimfuno ezingqongqo zokuxina. yenkqubo yolawulo lwemibhobho ejikeleze yonke inkqubo yokwakha yobunjineli.

Imiba: umbuzo wokuvuza kombhobho unokuhlalutywa ukusuka kumanqanaba amabini ezinto ezibonakalayo kunye nokusebenza kwangempela kokwakhiwa kobunjineli. Izinto ezisetyenziswayo: Izinto zezinto ezisetyenziswayo zibandakanya: amandla oxinzelelo lwemibhobho yokufakelwa kunye nemibhobho ayikho kumgangatho; Imibhobho kunye nemibhobho inemingxuma yesanti; Ufakelo lombhobho kamva lonakaliswa yimiba yabantu. Le meko iye yachukunyiswa ngabadali, umgangatho wombhobho we-galvanized ungaphezulu kwengqiniba, olu hlobo lwe-elbow eseleyo ubukhulu becala ubukhulu bodonga lwe-arc yangaphakathi lubhityile kakhulu okanye umngxuma wesanti, iliso lomntu lidla ngokuba nzima ukulifumana. . Umgangatho wezinto zombhobho weplastiki ngokuqhelekileyo ulungile kakhulu, kwaye into yokuvuza idla ngokubangelwa ukutshatyalaliswa kofakelo ngabanye abasebenzi bomsebenzi wobugcisa. Ubunjineli bokwakha inqanaba lomsebenzi osebenzayo: imiba yentsimi yokwakha yobunjineli ibandakanya: ukusetyenzwa komsonto wombhobho wagalvanized akudluli; Umbhobho socket joint ayiqinanga. Oku kukwayinto eqhelekileyo. Ukuvuza kwesokethi yombhobho wokuhambisa amanzi kumbalwa kakhulu. Uninzi lwezinto ezibonisa olu hlobo lombuzo lulwakhiwo lobunjineli obungenankathalo. Xa umbhobho udityanisiwe, akulungile ukulibala iglue okanye ukuhlaba ngokujulile. Ukumakishwa okunzulu, kulula ukuyilawula kwaye kulula ukuyibuza.

Izindlela zokuthintela kunye nezisombululo: lawula ngokungqongqo inkqubo yokuthenga, ukubuza ngokucophelela. Rekhoda ukusetyenziswa kofakelo lwemibhobho kunye nemibhobho yazo zonke iibhetshi kwaye uyibuyisele ngokukhawuleza xa kukho nawaphi na amathandabuzo afunyenweyo. Kwizixhobo zepayipi zePPR, i-ductility yesisombululo ukuthatha amanyathelo okuthintela. Iindlela zobugcisa zingasetyenziselwa: ukubekwa kwemibhobho engangcwatywa ngokuthe ngqo, kufuneka kuthathelwe ingqalelo isisombululo sombhobho wokwandiswa kwe-thermal kunye ne-contract contraction deformation yeendlela zobugcisa. I-ductility yombhobho kufuneka ibuyekezwe ngengalo esongwayo yombhobho kangangoko kunokwenzeka; Xa imibhobho ingasetyenziswa njengembuyekezo yendalo, ezinye iindlela zembuyekezo kufuneka zisetyenziswe. Kufuneka kubekho imbuyekezo yokulinganisa ii-main ukulinganisa izinyusi, ukulinganisa iinqununu ukuya kwizinyusi, kunye nezinyusi ukuya kumaleko ngaphandle kokuchaphazela omnye nomnye xa i-ductility yombhobho yandiswa. Xa ufaka umbhobho onqamlekileyo okanye umbhobho wokunyuka, indawo yangaphakathi kufuneka yakhiwe ngokufanelekileyo, kwaye umbhobho owenziwe "U" kufuneka usetyenziswe ukuhlawulela ukuguqulwa. Bonisa imibuzo yokuvuza kwamanzi, ukukhangela indawo yokuphuma kwamanzi, ukukhangela indawo yokuphuma kwamanzi emva kokuhlalutya izinto. Emva koko, amanyathelo afanelekileyo athatyathwe ukusombulula ingxaki: buyisela izixhobo zemibhobho engafanelekanga kunye nemibhobho; Ukuba ukusebenza kwangempela kokwakhiwa kobunjineli akudluli umgangatho, kuya kuphinda kusetyenzwe kwaye kuveliswe ukususela ekuqaleni. Ngenxa yombhobho wePPR oveliswe ngokwandiswa kwe-thermal kunye nokunciphisa okubandayo, unqumle icandelo lombhobho ukuze uthabathe amanyathelo obugcisa angasentla ukwenza ukulungiswa.

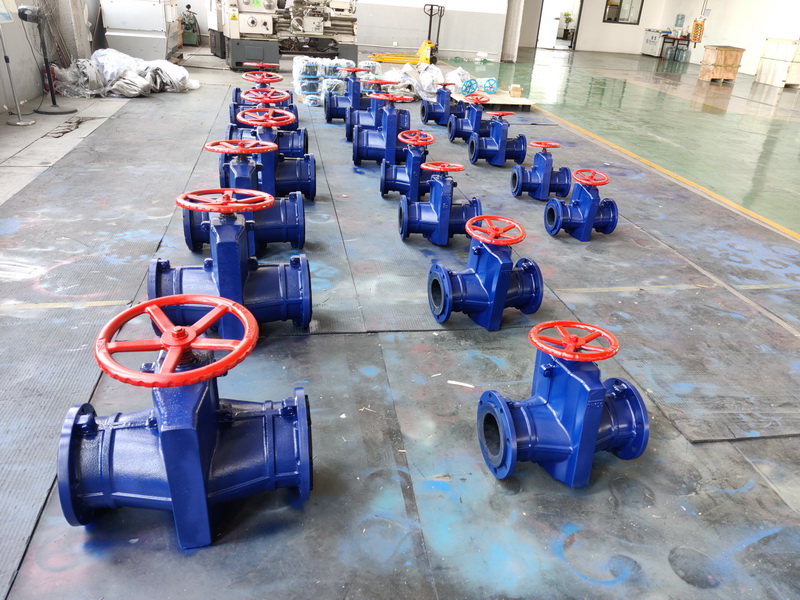

I-3, ukukhethwa kunye nokufakwa kwevalve yesango kunye neendlela zokuthintela

Imiba yokuvelisa: ukhetho olungenangqiqo lweentlobo zevalve yesango: uhlobo lwevalve kunye nomsebenzi wenkqubo yokulawula umbhobho kunye noxinzelelo olusebenzayo aluhambelani, ivalve yeglowubhu kunye neglowubhu yeglowubhu exutywe ukusetyenziswa, i-disc valve kunye nokusetyenziswa kwevalve edibeneyo, i-Angle globe valve kunye neglobhu ivalve exutyiweyo kunye nokusetyenziswa okuxutyiweyo kwevalve yesikhondo esimnyama, ukusebenza kwemibhobho nokugcinwa kwayo kuneziphumo ezibi. Indibano yevalvu yesango ayifanelekanga ukuba isebenze kwaye igcinwe. Ukujonga indawo yesixhobo sevalvu akukho ngqiqweni kunye neminye imibuzo.

Iindlela zokuthintela: xa isixhobo siqwalasela ukusebenza kwangempela kunye nokugcinwa kwendawo yangaphakathi, nikela ingqalelo ekuphakameni kwesixhobo kunye ne-rocker house orientation; Ukuba iivalve ezimbini zesango ziqhagamshelwe ngokukhawuleza kwaye isithuba phakathi kweebholiti ze-ankile sifutshane, ihupu yombhobho kufuneka yongezwe phakathi kweevalve ezimbini. Iivalvu zokukhangela kufuneka zichongwe ngotolo. Ivalve yokujonga i-valve yokuphuma kwetanki yokugcina amanzi ephantsi kufuneka ibekwe ngaphezulu kwe-1m kude ne-tank ephantsi kwamanzi ukuququzelela ukuma okuchanekileyo kwevalve yokukhangela, okanye ukusetyenziswa kwevalve yokujonga ukukhuhlana okuphantsi.

4, imiba yombuzo wengxolo kunye nezisombululo

Izinto zokuvelisa: xa uxinzelelo olusebenzayo lonikezelo lwamanzi kunye nombhobho wokuhambisa amanzi udlula i-0.3-0.4mpa kunye nobude bombhobho ≤20mm kwaye umbhobho ude, umbhobho uya kuvelisa ingxolo kunye nokungcangcazela, okubangelwa kakhulu yi-co-vibration eyenziwa amandla okuqhuba amanzi akhawulezayo kunye nenkqubo yokulawula imibhobho. Umbhobho wokuhambisa amanzi Umbuzo wengxolo: umbhobho wokuhambisa amanzi awugcwalanga kwaye ubaleka ngamandla, ingxolo ayinakuthintelwa, kunye nomonakalo wemathiriyeli yombhobho. Izinto ezibonakalayo zokuvavanya zibonisa ukuba xa ukuhamba okupheleleyo kwepayipi ye-DN100 yi-2.7L / s, ixabiso lengxolo ye-drainpipe ye-iron cast yi-46.5dB, kunye nexabiso lengxolo yepayipi ye-PVC-U yi-58dB. Ke ngoko, umbhobho othambileyo wentsimbi kufuneka usetyenziswe kumagumbi aphezulu afuna ukuzola. Umbhobho omtsha we-fiberpipe we-polyurethane we-foam wokunciphisa ingxolo ye-PSP, isiphumo sokugquma isandi silunge kakhulu, ixabiso libiza kancinci, linokusetyenziswa kwakhona.

Iindlela zokuthintela: iindlela zokukhusela amakhadi ziquka ngokufanelekileyo ukwandisa umbhobho, usebenzisa irabha ethambileyo edibeneyo, ukongeza ipleyiti yerabha phakathi kwesakhelo sokuxhasa kunye nombhobho kunye noxinzelelo lokulawula ivalve yokulawula uxinzelelo, njl. zilungiswe ngokuphindaphindiweyo ukunciphisa ingxolo ibencinci.

Ivalve yesango esetyenziswa ixesha elide, ngaba uyazi ukuba ungaqinisekisa njani ukuqina kwevalve yesango?

I-piston kunye neeprotrusions zevalve yesango loxinzelelo oluphezulu zingonakala kwaye izitywina zincitshiswe emva kwenkonzo ende. Ukulungisa umphezulu ophumayo ngumsebenzi omkhulu nobalulekileyo. Indlela ekhethekileyo yokulungiswa kukugaya. Ngowona monakalo mkhulu womphezulu ophumayo, kuqala kutshizwe i-welding emva kokulungiswa kwe-nc kwaye emva koko kugaywe.

Ixesha lokuposa: Jun-15-2022