Ukulawulwa okujwayelekile kokumiswa kwe-valve kudinga indlela yokulungiselela imodeli ye-valve

Lo mthetho usebenza ekumisweni kwe-valve yesango, i-globe valve, i-valve yebhola, i-butterfly valve kanye ne-valve yokunciphisa ukucindezela embonini ye-petrochemical. I-valve yokuhlola, i-valve yokuphepha, i-valve elawulayo, ukusetha isicupho bheka imithethonqubo efanele. Lo mthetho awusebenzi ekumisweni kwamavalvu emapayipini okuhambisa amanzi angaphansi komhlaba namapayipi okudonsa amanzi.

Lo mthetho usebenza ekumisweni kwe-valve yesango, i-globe valve, i-valve yebhola, i-butterfly valve kanye ne-valve yokunciphisa ukucindezela embonini ye-petrochemical. I-valve yokuhlola, i-valve yokuphepha, i-valve elawulayo, ukusetha isicupho bheka imithethonqubo efanele. Lo mthetho awusebenzi ekumisweni kwamavalvu emapayipini okuhambisa amanzi angaphansi komhlaba namapayipi okudonsa amanzi.

1 Umgomo wesakhiwo se-valve

1.1 Amavalvu kufanele ahambisane namapayipi kanye neshadi lokugeleza kwezinsimbi (P>

1.2 Ivalvu kufanele ihlelwe endaweni efinyeleleka kalula, kulula ukuyisebenzisa nokuyinakekela. Ama-valve asemgqeni wamapayipi kufanele ahlelwe phakathi nendawo, futhi isiteji sokusebenza noma isitebhisi kufanele sicatshangelwe.

Izidingo zokuma kwevalvu

2.1 Uma amapayipi amapayipi aphumayo angena futhi aphuma exhunywe amapayipi amakhulu emhubheni wepayipi wefekthri yonke, ivalvu yokunqamula izosethwa. Indawo yokufaka i-valve kufanele ihlelwe phakathi ohlangothini olulodwa lwendawo yedivayisi, futhi isiteji sokusebenza esidingekayo noma isiteji sokulungisa kufanele simiswe.

2.2 Amavalvu adinga ukusebenza njalo, ukugcinwa nokulungiswa kabusha kufanele abekwe endaweni okufinyeleleka kalula kuyo phansi, ipulatifomu noma iladi. Ama-valve omoya kanye nawogesi kufanele ahlelwe ngendlela efinyeleleka kalula.

2.3 Amavalvu angadingi ukusebenza njalo (asetshenziswa kuphela lapho kuvulwa noma kumiswa) kufanele futhi abekwe lapho amaladi esikhashana angamiswa khona uma engakwazi ukuhlinzelwa phansi.

2.4 Ubude phakathi kwesikhungo se-valve handwheel kanye nendawo yokusebenza yi-750 ~ 1500mm, futhi ukuphakama okuphezulu

I-1200mm, i-valve ikhuphuka ifike ku-1500 ~ 1800mm ngaphandle kokusebenza njalo. Lapho ubude bokufaka bungenakuncishiswa futhi ukusebenza okuvamile kuyadingeka, isiteji sokusebenza noma isinyathelo kufanele sisethwe ngesikhathi sokuklama. Amavalvu amapayipi nezinto zokusebenza ezinemidiya eyingozi akufanele abekwe phakathi nobude bekhanda lomuntu.

2.5 Uma isikhungo se-valve handwheel singaphezu kuka-1800mm ukusuka endaweni yokusebenza, kuhle ukusetha ukusebenza kwe-sprocket. Iketanga le-sprocket kufanele libe ngu-800mm ukusuka phansi, futhi i-hook ye-sprocket kufanele isethwe, futhi indawo engezansi yeketanga kufanele ilengiswe odongeni noma ikholomu eseduze, ukuze ingaphazamisi iphaseji.

2.6 Ngevalvu esethwe ku-groove, lapho isembozo se-groove singasetshenzwa ngokuvula i-groove, isondo lesandla se-valve akufanele libe ngu-300mm ngaphansi kwesembozo se-groove. Uma ingaphansi kuka-300mm, i-valve extension rod kufanele isethwe ukuze isondo lesandla libe phakathi kuka-100mm ngaphansi kwesembozo se-groove.

2.7 Uma ivalvu esethwe emseleni wepayipi idinga ukusetshenzelwa phansi noma ifakwe ngaphansi (isiteji) sesitezi sangaphambilini, induku yokunweba i-valve ingasethwa ukuthi inwebeke epuleti lekhava lomsele, phansi kanye nesiteji ukusebenza. Indawo yokusebenza yebanga lesondo lesandla lenduku yokunweba ingu-1200mm. Amavavu AMA-DN40 AMA-DN40 NOMA NGAPHANSI NOKUXHUMANA OKUNEMICHUPHE AKUMELE ASEBENZE NGE-SPROCKE NOMA IZINDIDI ZOKUNWETHWA UKUZE KUGWEME UKUKALIZA IVAVVU. Ngokuvamile, i-valve kufanele isetshenziswe kancane ngangokunokwenzeka ngama-sprockets noma izinduku zokunweba.

2.8 Ibanga eliphakathi konqenqema lweplathifomu ye-valve handwheel edidayo ehlelwe endaweni yesikhulumi akufanele ibe nkulu kuno-450mm. Uma isiqu se-valve nesondo lesandla kunwebeka engxenyeni engenhla yesikhulumi futhi ukuphakama kungaphansi kuka-2000mm, qinisekisa ukuthi isiqu nesondo lesandla akuthinti ukusebenza nokudlula komqhubi ukuze agweme ukulimala komuntu siqu.

3. Ukusetha izidingo zamavalvu amakhulu

3.1 Amavalvu amakhulu kufanele asetshenziswe ngendlela yokudlulisa igiya, futhi indawo edingekayo yendawo yomshini wokudlulisa kufanele kubhekwe lapho kusetha. Ngokuvamile, AMASIZE EVAVAVU amakhulu kunamakilasi alandelayo KUFANELE acatshangelwe ukuze Asetshenziswe ngezindlela ezihloselwe.

3.2 Amavalvu amakhulu kufanele ahlinzekwe ngokusekela ohlangothini olulodwa noma nhlangothi zombili zevalvu, angeke abekwe epayipini elifushane elidinga ukukhishwa ngesikhathi sokulungiswa, futhi angeke aphazamise ukusekelwa kwepayipi lapho kukhishwa ivalvu. Ngokuvamile, ibanga phakathi kokusekela kanye ne-valve flange kufanele libe likhulu kuno-300mm.

3.3 Indawo yokufakwa kwamavalvu amakhulu izoba nendawo lapho kusetshenziswa khona amakhreni, noma amadavithi nemishayo kuzocatshangelwa.

4. Ukusetha izidingo zamavalvu kumapayipi avundlile

4.1 Ngaphandle kwezidingo ezikhethekile zenqubo, isondo lesandla levalvu efakwe epayipini elivundlile elivamile akufanele libheke phansi, ikakhulukazi ivalvu esembhobhweni oyingozi akufanele ibheke phansi. Ukuma kwesondo lesandla se-valve kunqunywa ngohlelo olulandelayo: mpo ukuya phezulu; Izinga; Ngokuqondile phezulu phezulu kwesokunxele nakwesokudla 45°; Iqonde phansi kwesokunxele nakwesokudla 45°; Ungehli uqonde phansi.

4.2 Ukufakwa okuvundlile kwe-valve yohlobo lwenduku evulekile, lapho kuvulwa i-valve, isiqu ngeke sithinte ukugeleza, ikakhulukazi uma isiqu sitholakala ekhanda noma edolweni lomqhubi.

Ezinye izidingo zokusetha i-valve

5.1 Imigqa emaphakathi yamavalvu kumapayipi ahambisanayo kufanele iqondaniswe ngokusemandleni. Uma ama-valve ehlelwa eduze komunye nomunye, ibanga lenethi phakathi kwamasondo ezandla akufanele libe ngaphansi kuka-100mm; Amavalvu nawo anganyakaziswa ukuze kuncishiswe ukuhlukana kwamapayipi.

5.2 Lapho i-diameter yegama, ingcindezi yegama kanye nohlobo lokuvaleka kwendawo yevalvu edingekayo ukuze kuxhunywe ukuvulwa kwepayipi lempahla kufana noma kufanelana ne-flange yokuvuleka kwepayipi lamathuluzi, izoxhunywa ngokuqondile ukuvulwa kwepayipi lemishini. Uma I-valve I-CONCAVE ivulekile, BUZA Uchwepheshe wezinto zokusebenza UKUZE anikeze ama-FLAnges ayi-convex ku-nozzle ehambisanayo.

5.3 Ngaphandle kwezidingo ezikhethekile zenqubo, ama-valve asemapayipini aphansi ombhoshongo, i-reactor, umkhumbi omile kanye nezinye izinto zokusebenza akufanele zihlelwe kusiketi.

5.4 Uma ipayipi legatsha likhishwa epayipini elikhulu, i-valve yokusika kufanele ibekwe engxenyeni evundlile yepayipi legatsha eduze kwempande yepayipi elikhulu, ukuze uketshezi lukhishwe ezinhlangothini zombili ze-valve. .

5.5 Ivalvu yokuvala ipayipi legatsha kugalari yamapayipi ayisetshenziswa njalo (* ukuze kulungiswe indawo yokupaka). Uma kungekho iladi elihlala njalo elimisiwe, isikhala sesitebhisi sesikhashana kufanele sicatshangelwe.

5.6 Uma i-valve yokucindezela okukhulu ivuliwe, amandla okuqala makhulu. Kuyadingeka ukusetha ukusekela ukusekela i-valve nokunciphisa ukucindezeleka kokuqala. Ubude bokufaka buyi-500 ~ 1200mm.

5.7 Ivalvu yamanzi omlilo kanye nevalve yesitimu somlilo endaweni yomngcele wedivayisi kufanele ihlakazwe futhi ihlelwe endaweni ephephile efinyeleleka kubasebenzisi uma kwenzeka ingozi.

5.8 Isethi yevalvu yepayipi lokusabalalisa isitimu esicisha umlilo lesithando sokushisa kufanele kube lula ukusebenza, futhi ibanga phakathi kwepayipi lokusabalalisa nomzimba wesithando akumele libe ngaphansi kuka-7.5m.

5.9 Uma ama-valve anentambo efakwa emapayipini, isixhumi esiphilayo kufanele sifakwe eduze kwevalvu ukuze sikhishwe.

5.10 I-valve yesemishi noma i-butterfly valve akufanele ixhunywe ngokuqondile ne-flange yamanye ama-valve kanye nokufakwa kwamapayipi, futhi ingxenye izokwengezwa phakathi nendawo.

Ipayipi elifushane elinama-flange emikhawulweni yomibili.

5.11 I-valve akufanele ithwale umthwalo osetshenzisiwe ukuze ugweme ukulimala kokucindezeleka ngokweqile ku-valve.

Indlela yokulungiselela imodeli ye-valve

Indlela yokulungiselela imodeli yevalvu:

Namuhla, izinhlobo eziningi ze-valve nezinto zokwakha, indlela yokulungiselela imodeli ye-valve nayo iyinkimbinkimbi ngokwengeziwe, imodeli ye-valve kufanele imele uhlobo lwe-valve, imodi yokushayela, ifomu lokuxhuma, izici zesakhiwo, ukucindezela okuzisholo, ukufakwa uphawu kwezinto ezibonakalayo, impahla ye-valve yomzimba nezinye izakhi. Ukumiswa kwemodeli ye-valve kunikeza lula ukuklama, ukukhethwa nokusabalalisa ama-valve. Nakuba izwe lethu linendlela yokumisa imodeli ye-valve inezinga elifanayo, kodwa kancane kancane alikwazi ukuhlangabezana nezidingo zokuthuthukiswa kwemboni yama-valve, okwamanje, abakhiqizi be-valve ngokuvamile basebenzisa indlela yabo yezinombolo, indlela yokuhlanganisa izinombolo ngeke isetshenziswe, okulandelayo Ithebula I inkampani yeningi labasebenzisi ukuthuthukisa inguqulo ephelele yendlela yenombolo yevalvu, ukuze uthole ireferensi yakho, Uma unemibuzo, sicela ushayele ku-021-57562898 ukuze uthole ukubonisana.

Indlela yokulungiselela imodeli yevalvu:

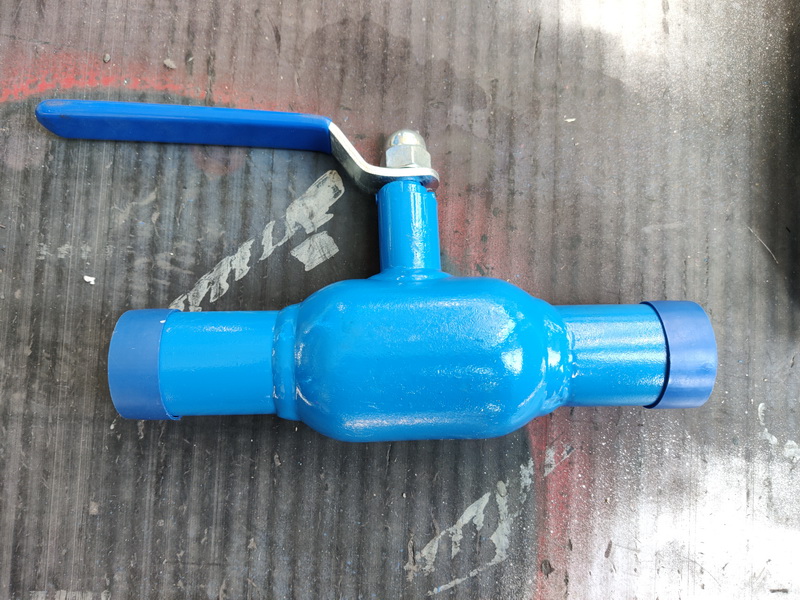

Le ndlela yokulungiselela yethula ngokuyinhloko ukulungiswa kwemodeli ye-valve evamile, ikhodi yohlobo, ikhodi yokushayela, ikhodi yefomu lokuxhuma, ikhodi yefomu yesakhiwo, ikhodi yendawo yokuvala uphawu, ikhodi yempahla yomzimba we-valve kanye nendlela yokumelela ikhodi yokucindezela. Leli zinga lisebenza kumodeli ye-valve yesango elivamile, imodeli ye-valve yeglobhu, imodeli yevalvu edonsa umoya, imodeli ye-valve uvemvane, imodeli ye-valve yebhola, imodeli ye-valve ye-diaphragm, imodeli ye-valve yepulaki, imodeli ye-valve yokuhlola, imodeli yevalvu yokuphepha, imodeli ye-valve yokunciphisa umfutho, isicupho se-steam imodeli, imodeli ye-valve yokudonsa, imodeli ye-plunger valve.

I-Standalization Administration isanda kukhipha "indlela yokulungiselela imodeli ye-valve"; Ihlongozwe yi-China Machinery Industry Federation, ngokuhambisana nemithetho ye-GB/T1.1-2009 yokuklama, indlela yokuhlanganisa imodeli yamavalvu yiKomiti Kazwelonke Yokumisa Amavalvu Ezobuchwepheshe (SAC/TC188) ebekwe endaweni eyodwa. Ngokuhambisana nokuhlelwa kwe-JB/T 308-2004.

Ukulandelana kwendlela yokulungiselela imodeli yevalvu:

“Iyunithi – uhlobo lwevalvu” kanye “neyunithi yesibili – imodi yokushayela] – [iyunithi lesithathu - ifomu lokuxhuma] – [amayunithi angu-4 - isakhiwo 】 kanye 【 iyunithi 5 - impahla evala umugqa noma uhlobo lwempahla] – > [amayunithi ayi-6 - ikhodi yokucindezela okulinganiselwe noma izinga lokushisa lokusebenza lekhodi yengcindezi yokusebenza] - [amayunithi ayi-7 - impahla yomzimba] - [amayunithi ayi-8 - ububanzi obujwayelekile 】

Okukhethekile okwengeziwe njenge-TAICHEN pinyin, okufushane kwe-TC

Isikhathi sokuthumela: Aug-17-2022