0102030405

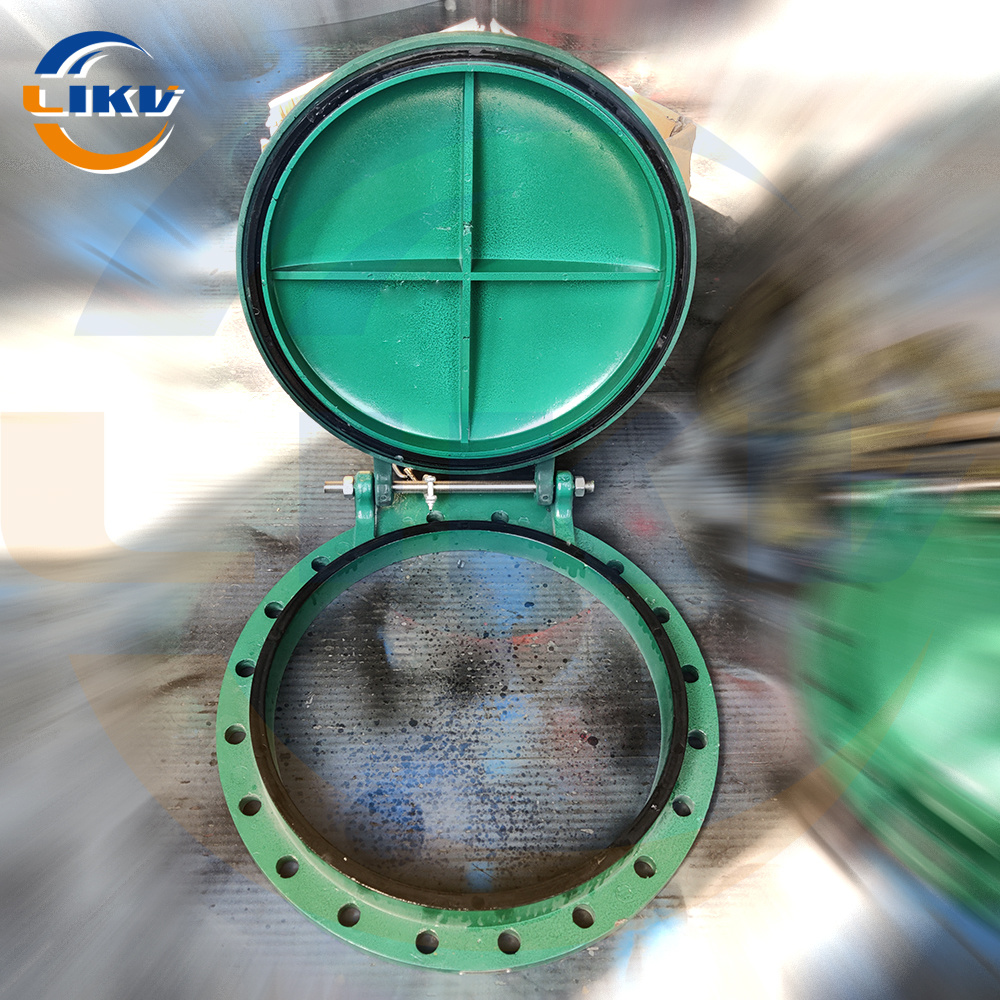

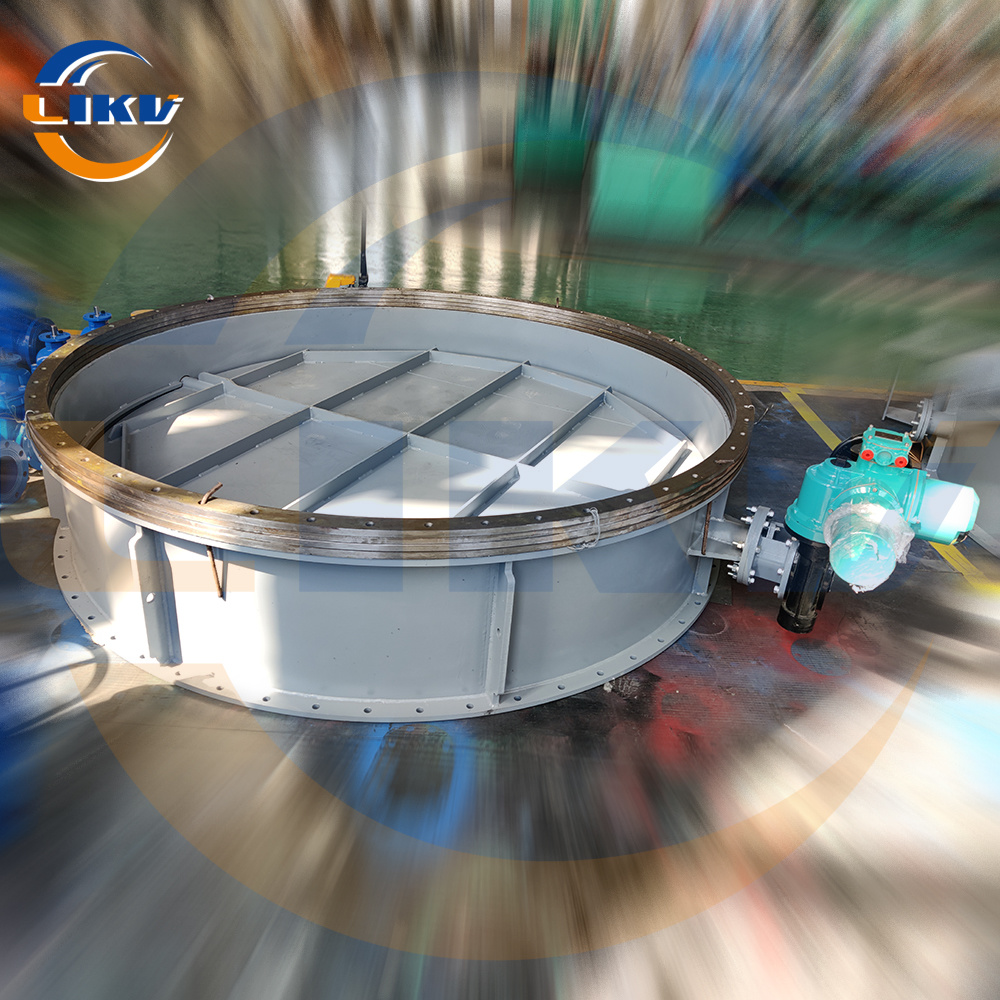

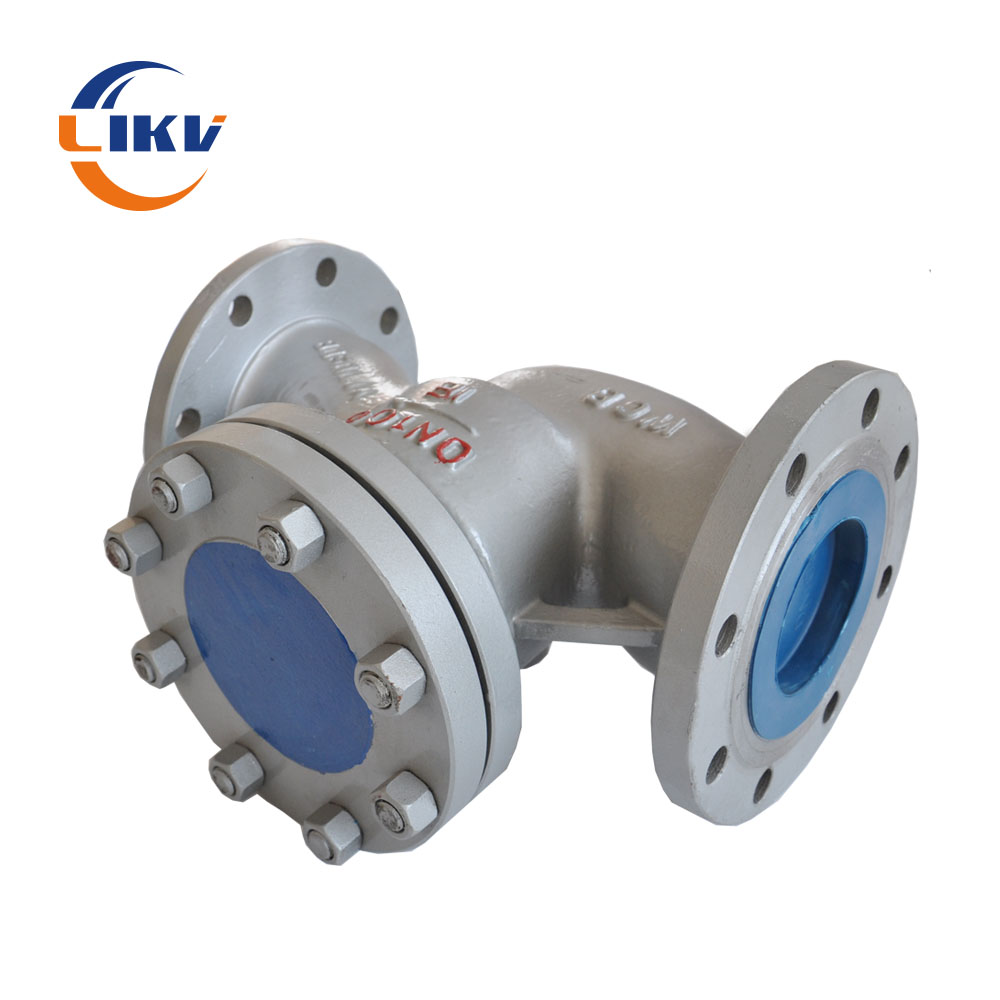

Special Price for Double Flange Cast Iron Dn50 Dn100 Swing Check Valve Ductile Iron Rubber Flap Valve

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most competitive prices. So Profi Tools offer you best value of money and we are ready to develop together with Special Price for Double Flange Cast Iron Dn50 Dn100 Swing Check Valve Ductile Iron Rubber Flap Valve, We are sincerely looking forward to cooperate with customers everywhere in the world. We believe we will satisfy you. We also warmly welcome clients to visit our business and purchase our products. We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most competitive prices. So Profi Tools offer you best value of money and we are ready to develop together with Check Valve, Check Valve Dn100, Swing Check Valve, We've got the best solutions and specialist sales and technical team.With the development of our company, we're able to deliver customers best products, good technical support, perfect after-sales service. Lifting check valve refers to the valve that automatically opens and closes the disc depending on the flow of the medium itself to prevent medium backflow, also known as check valve, one-way valve, counterflow valve, and back pressure valve. Check valve is an automatic valve. Its main function is to prevent medium backflow, reverse pump and drive motor, and release of container medium. Check valves can also be used in pipelines to supply auxiliary systems where pressure may rise above system pressure. Check valves can be divided into swing check valves (rotating according to the center of gravity) and lift check valves (moving along the axis). Technical data PN(MPa)Nominal pressure 1.6 2.5 4.0 (MPa)Test pressure Shell strength test 2.4 3.75 6.0 Seal test (Liquid) 1.76 2.75 4.4 Seal test (Gas) 0.5~0.7 Suitable medium water,steam,oil PNiter acids Roil Suitable temperature ≤425 ≤100 ≤550 Meterial of main parts No. Part name Meterial ASTM GB 1 Valve body WCB, WC1,WC6,WC9,C5 CF8,CF8M,CF8C,CF3,CF3M WCB,WC1,WC6,WC9,C5 CF8,CF8M,CF8C,CF3,CF3M 2 Valve disc WCB,WC1,WC6,WC9,C5 CF8,CF8M,CF8C,CF3,CF3M WCB,WC1,WC6,WC9,C5 CF8,CF8M,CF8C,CF3,CF3M 3 Stud bolts A193-B7,A320-B8,A193-B8M 35CrMoA,25Cr2MoV,0CM8Ni9,0Cr17Ni12Mo2 4 Hex nuts A194-2H,A194-8,A194-8M 45,35CrMoA,25Cr2MoV, 0Cr18Ni9,0Cr17Ni12Mo2 5 Gasket Flexible graphite + stainless steel Flexible graphite + stainless steel 6 valve bonnet A105,F11,F22,F5,F9 F304, F316, F321, F304L, F316L 25,1Cr18Ni9Ni,0Cr18Ni12Mo2Ti 20Cr1Mo1V,25Cr2MoV Main dimensions PN(MPa) DN(mm) L H D D1 D2 D6 b f f2 Z-ød 1.6 15 130 77 95 65 45 - 14 2 - 4-14 20 150 77 105 75 55 - 14 2 - 4-14 25 160 80 115 85 65 - 16 2 - 4-14 32 180 85 135 100 78 - 16 2 - 4-18 40 200 95 145 110 85 - 16 3 - 4-18 50 230 105 160 125 100 - 16 3 - 4-18 65 290 120 180 145 120 - 18 3 - 4-18 80 310 130 195 160 135 - 20 3 - 8-18 100 350 140 215 180 155 - 20 3 - 8-18 125 400 155 245 210 185 - 22 3 - 8-18 150 480 180 280 240 210 - 24 3 - 8-23 200 600 245 335 295 265 - 26 3 - 12-23 2.5 15 130 100 95 65 45 - 16 2 - 4-14 20 150 105 105 75 55 - 16 2 - 4-14 25 160 120 115 85 65 - 16 2 - 4-14 32 180 130 135 100 78 - 18 2 - 4-18 40 200 135 145 110 85 - 18 3 - 4-18 50 230 149 160 125 100 - 20 3 - 4-18 80 310 169 195 160 135 - 22 3 - 8-18 100 350 194 230 190 160 - 24 3 - 8-23 150 480 255 300 250 218 - 30 3 - 8-25 200 600 305 360 310 278 - 34 3 - 12-25 4.0 15 130 100 95 65 45 40 16 2 4 4-14 20 150 105 105 75 55 51 16 2 4 4-14 25 160 120 115 85 65 58 16 2 4 4-14 32 180 130 135 100 78 66 18 2 4 4-18 40 200 135 145 110 85 76 18 3 4 4-18 50 230 149 160 125 100 88 20 3 4 4-18 80 310 169 195 160 135 121 22 3 4 8-18 100 350 194 230 190 160 150 24 3 4.5 8-23 150 480 255 300 250 218 204 30 3 4.5 8-25 200 600 305 375 320 282 260 38 3 4.5 12-30