0102030405

Online Exporter Dn250dn300dn350 Desulfurization Butterfly Valve

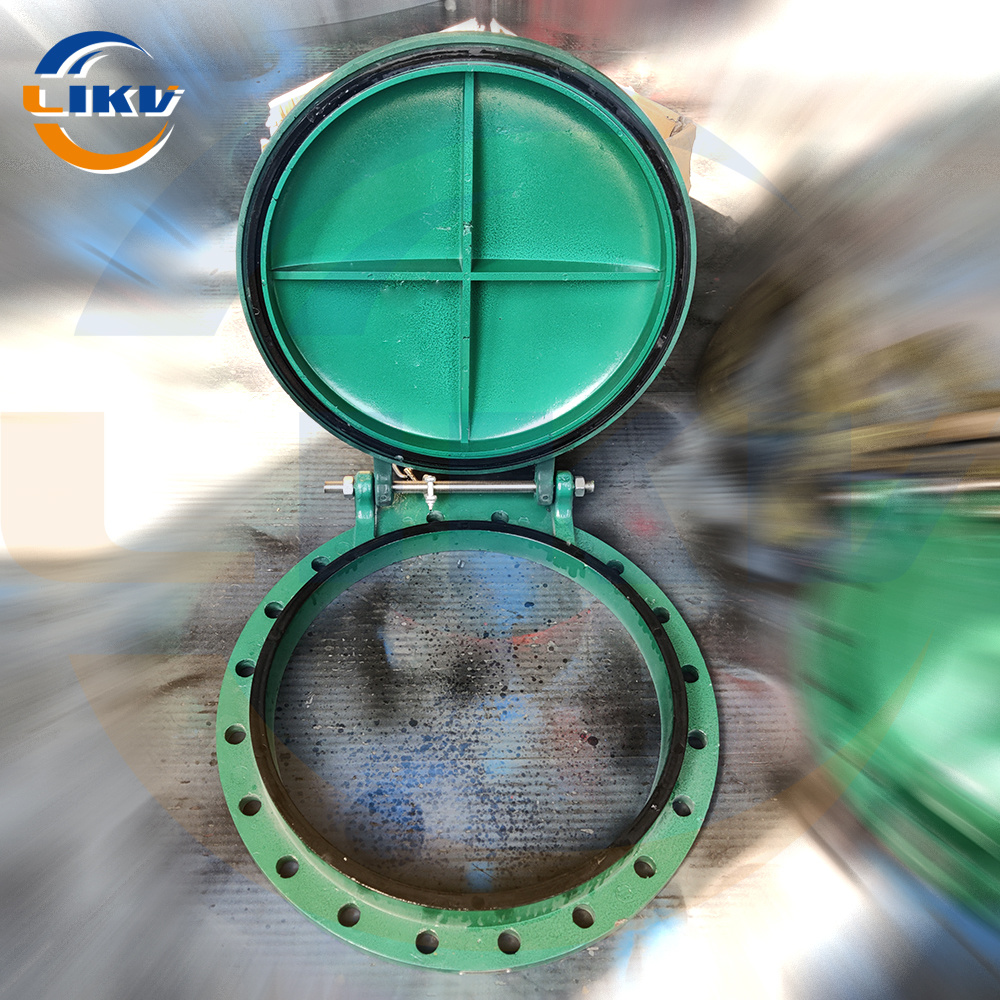

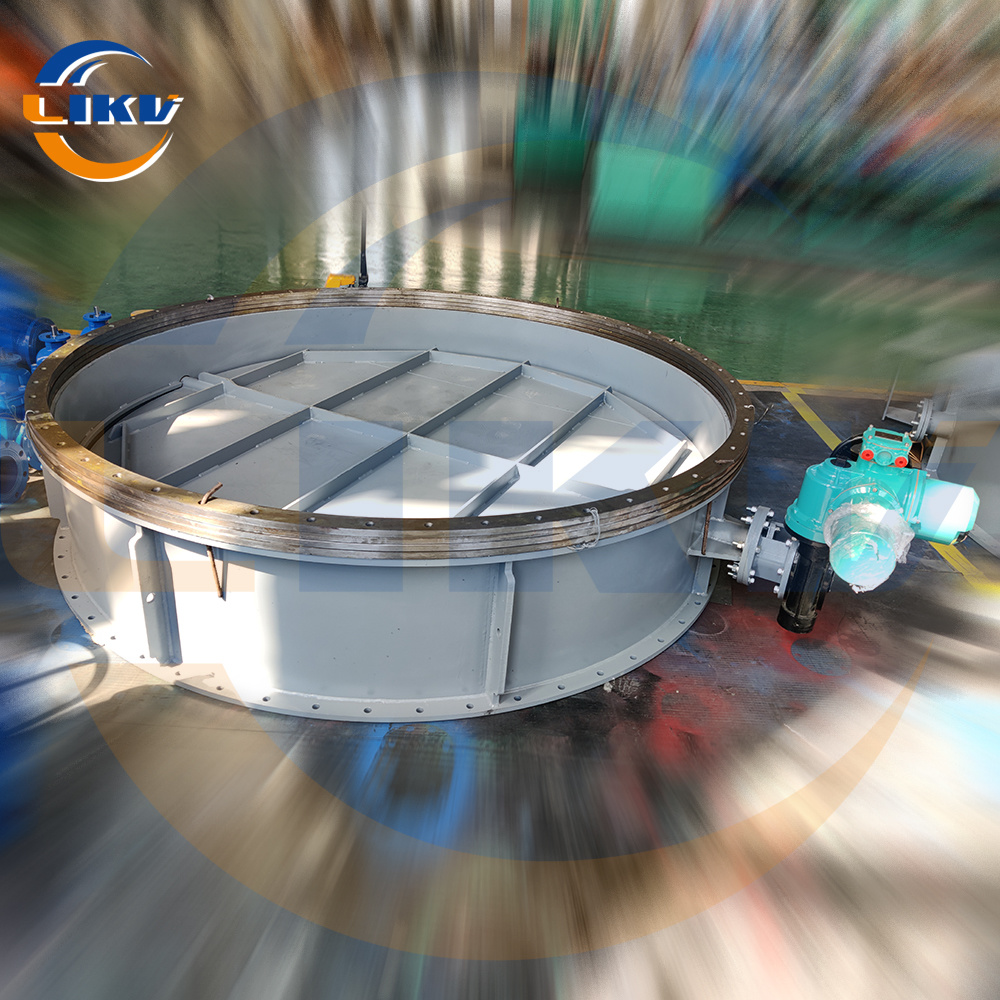

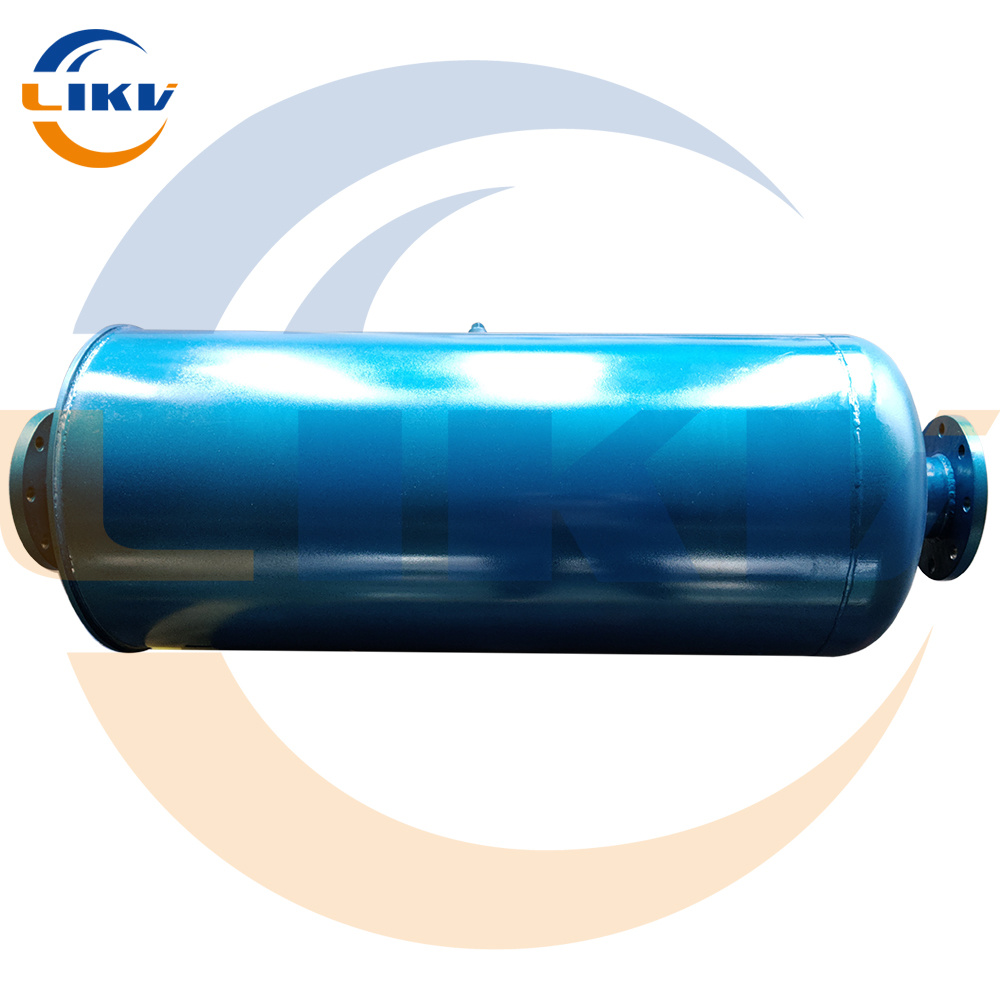

Being supported by an highly developed and specialist IT group, we could supply technical support on pre-sales & after-sales service for Online Exporter Dn250dn300dn350 Desulfurization Butterfly Valve, We, with open up arms, invite all fascinated potential buyers to visit our website or contact us straight for further information. Being supported by an highly developed and specialist IT group, we could supply technical support on pre-sales & after-sales service for Desulfurization Butterfly Valve, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter. Always adhere to the best design principles, fully considering the corrosion and wear of desulfurization slurry on the valve, to ensure that the valve plate lining is directly able to contact the slurry components, while other components are not corroded by limestone (or limestone) slurry. Therefore, the valve body and stem do not need to use expensive alloy (2205) material, thus greatly saving costs. Multifunctionality It is widely used in pipelines of petroleum, chemical industry, food, medicine, paper making, hydropower, ship, water supply and drainage, gold treatment, energy and other systems. It is suitable for a variety of corrosive gases, liquids, semi-liquids and solid powder media. Product parameters Applicable temperature Applicable medium Natural rubber≤85℃ Gypsum slurry, limestone slurry, recycled water, process water, wastewater EPDM≤100℃ Major Parts Materials Name Material Science valve body Gray Iron, Ductile Iron, Carbon Steel Disc Carbon steel coated rubber, carbon steel coated fluoroplastics, stainless steel duplex stainless steel plate 1.4529、C276 valve seat Natural Rubber, EPDM, Rubber Stem Stainless steel、 2Cr13、304