0102030405

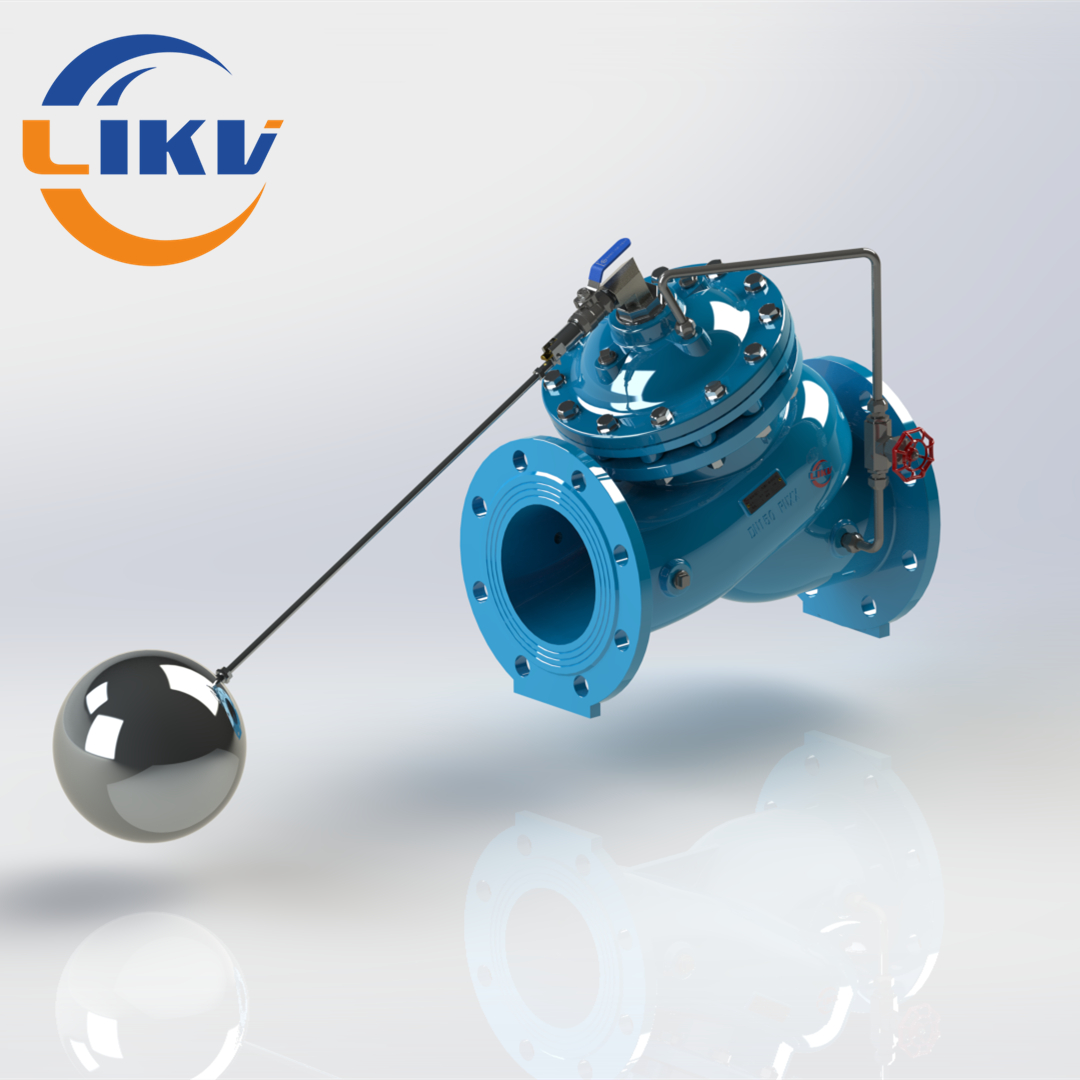

China OEM China 100X Ductile Iron Water Tank Float Ball Valve

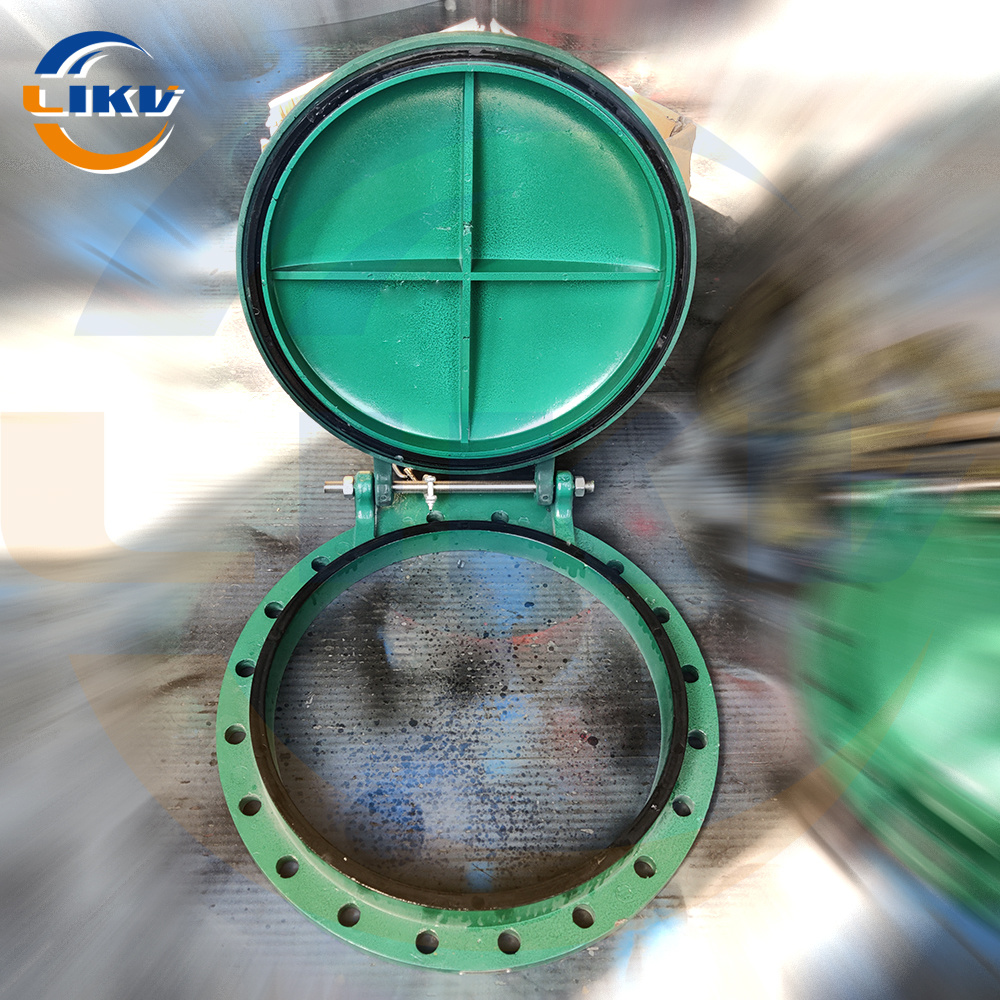

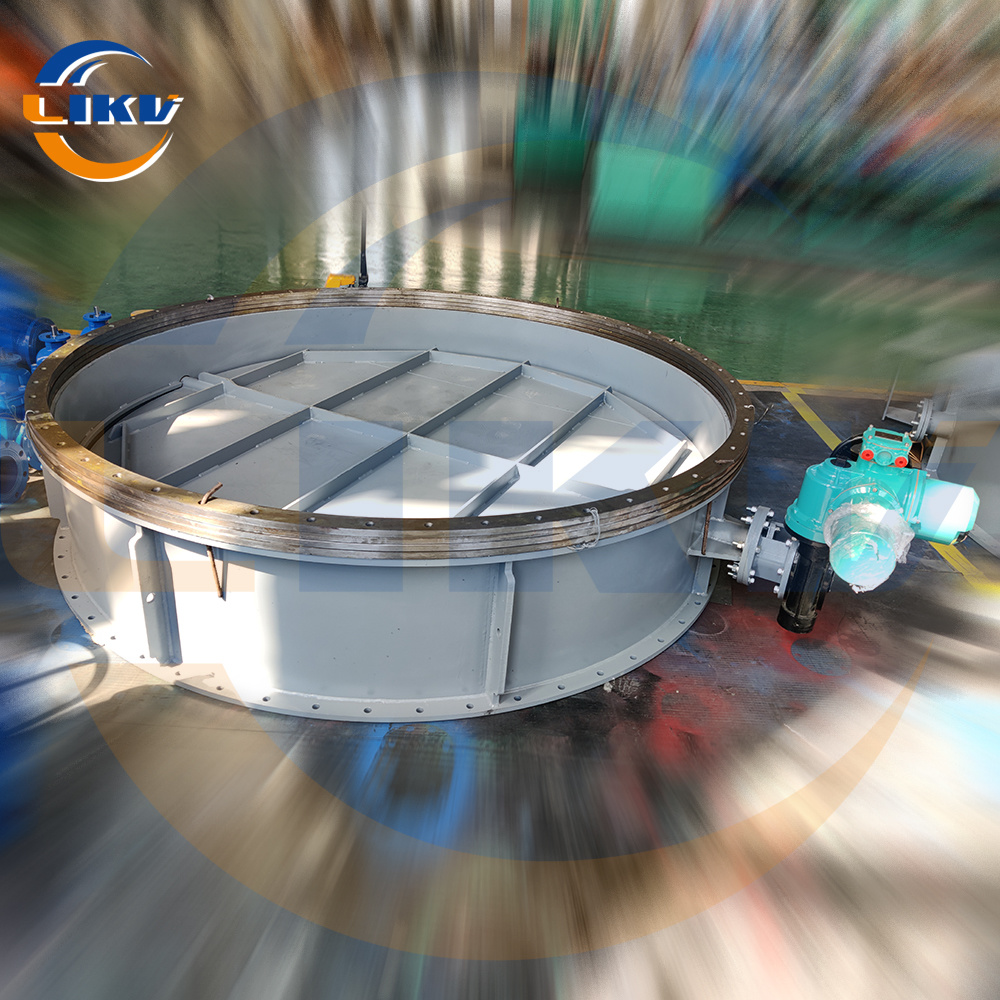

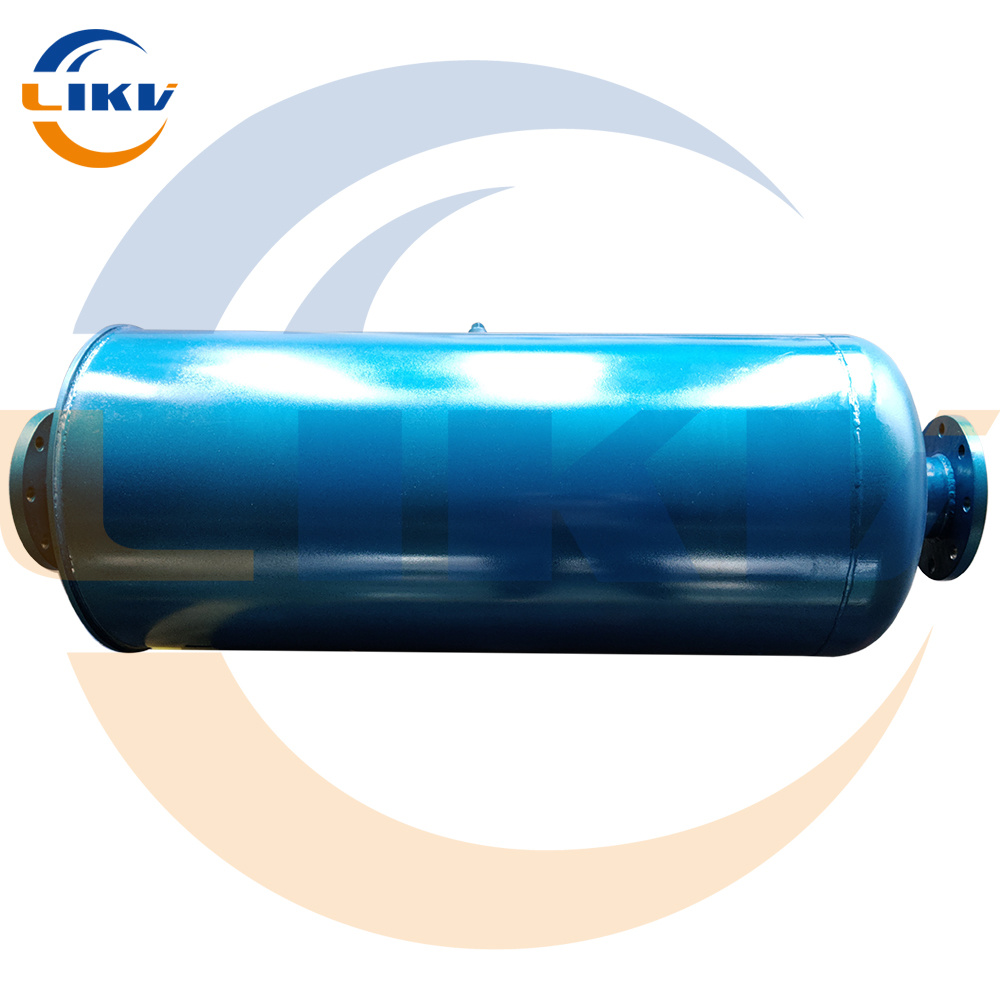

Usually customer-oriented, and it's our ultimate focus on being not only one of the most responsible, trustable and honest provider, but also the partner for our clients for China OEM China 100X Ductile Iron Water Tank Float Ball Valve, Good quality is factory' existence , Focus on customer' demand is the source of company survival and advancement, We adhere to honesty and superior faith working attitude, hunting forward towards your coming ! Usually customer-oriented, and it's our ultimate focus on being not only one of the most responsible, trustable and honest provider, but also the partner for our clients for China Industrial Valve, Floating Ball Valve, Our solutions have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll offer the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together. 1. There is no friction between opening and closing. This function completely solves the problem that the sealing surface of traditional valves is affected by mutual friction between sealing surfaces. 2. Top mounted structure. The valve installed on the pipeline can be directly inspected and repaired online, which can effectively reduce the shutdown of the device and reduce the cost. 3. Single seat design. The problem that the medium in the cavity of the valve affects the use safety due to abnormal pressure rise is eliminated. 4. Low torque design. The valve stem with special structural design can be opened and closed easily with only a small handle. 5. Wedge seal structure. The valve is sealed by pressing the ball wedge onto the valve seat by the mechanical force provided by the valve stem, so that the tightness of the valve is not affected by the change of pipeline differential pressure, and the sealing performance is reliably guaranteed under various working conditions. 6. Self cleaning structure of sealing surface. When the ball tilts away from the valve seat, the fluid in the pipeline passes through the sealing surface of the ball at 360 °, which not only eliminates the local scouring of the valve seat by the high-speed fluid, but also washes away the accumulation on the sealing surface, so as to achieve the purpose of self-cleaning. working pressure PN10, PN16 testing pressure shell: 1.5 times rated pressureseat: 1.1 times rated pressure working temperature -10 °C to 80°C (NBR)-10 °C to 120°C (EPDM) suitable media water Main dimension table DN 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 450 L 150 160 180 200 203 216 241 292 330 356 495 622 622 787 914 978 H1 179 179 179 210 210 215 245 305 365 415 510 560 560 696 735 677 H 342 342 342 395 395 406 430 510 560 585 675 730 760 840 910 1027 Products Detailes Process Application