Remote Water Level Control Floating Valve

1. There is no friction between opening and closing. This function completely solves the problem that the sealing surface of traditional valves is affected by mutual friction between sealing surfaces.

2. Top mounted structure. The valve installed on the pipeline can be directly inspected and repaired online, which can effectively reduce the shutdown of the device and reduce the cost.

3. Single seat design. The problem that the medium in the cavity of the valve affects the use safety due to abnormal pressure rise is eliminated.

4. Low torque design. The valve stem with special structural design can be opened and closed easily with only a small handle.

5. Wedge seal structure. The valve is sealed by pressing the ball wedge onto the valve seat by the mechanical force provided by the valve stem, so that the tightness of the valve is not affected by the change of pipeline differential pressure, and the sealing performance is reliably guaranteed under various working conditions.

6. Self cleaning structure of sealing surface. When the ball tilts away from the valve seat, the fluid in the pipeline passes through the sealing surface of the ball at 360 °, which not only eliminates the local scouring of the valve seat by the high-speed fluid, but also washes away the accumulation on the sealing surface, so as to achieve the purpose of self-cleaning.

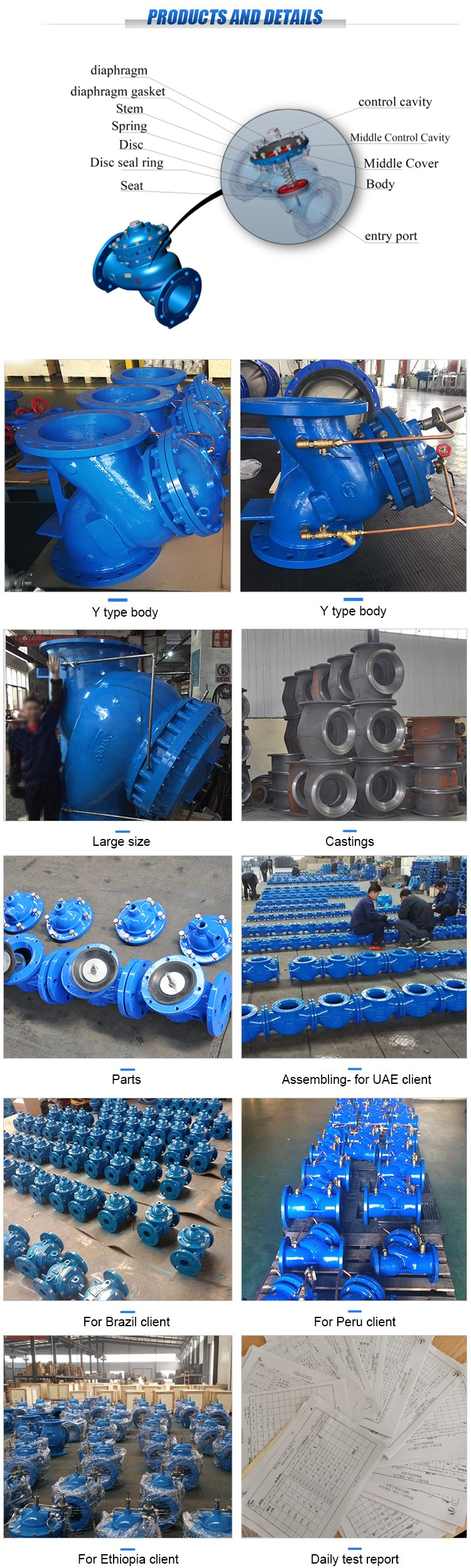

Products Detailes

| working pressure | PN10, PN16 |

| testing pressure | shell: 1.5 times rated pressureseat: 1.1 times rated pressure |

| working temperature | -10 °C to 80°C (NBR)-10 °C to 120°C (EPDM) |

| suitable media | water |

Main dimension table

| DN | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 |

| L | 150 | 160 | 180 | 200 | 203 | 216 | 241 | 292 | 330 | 356 | 495 | 622 | 622 | 787 | 914 | 978 |

| H1 | 179 | 179 | 179 | 210 | 210 | 215 | 245 | 305 | 365 | 415 | 510 | 560 | 560 | 696 | 735 | 677 |

| H | 342 | 342 | 342 | 395 | 395 | 406 | 430 | 510 | 560 | 585 | 675 | 730 | 760 | 840 | 910 | 1027 |

Products Detailes

Certificates

Process

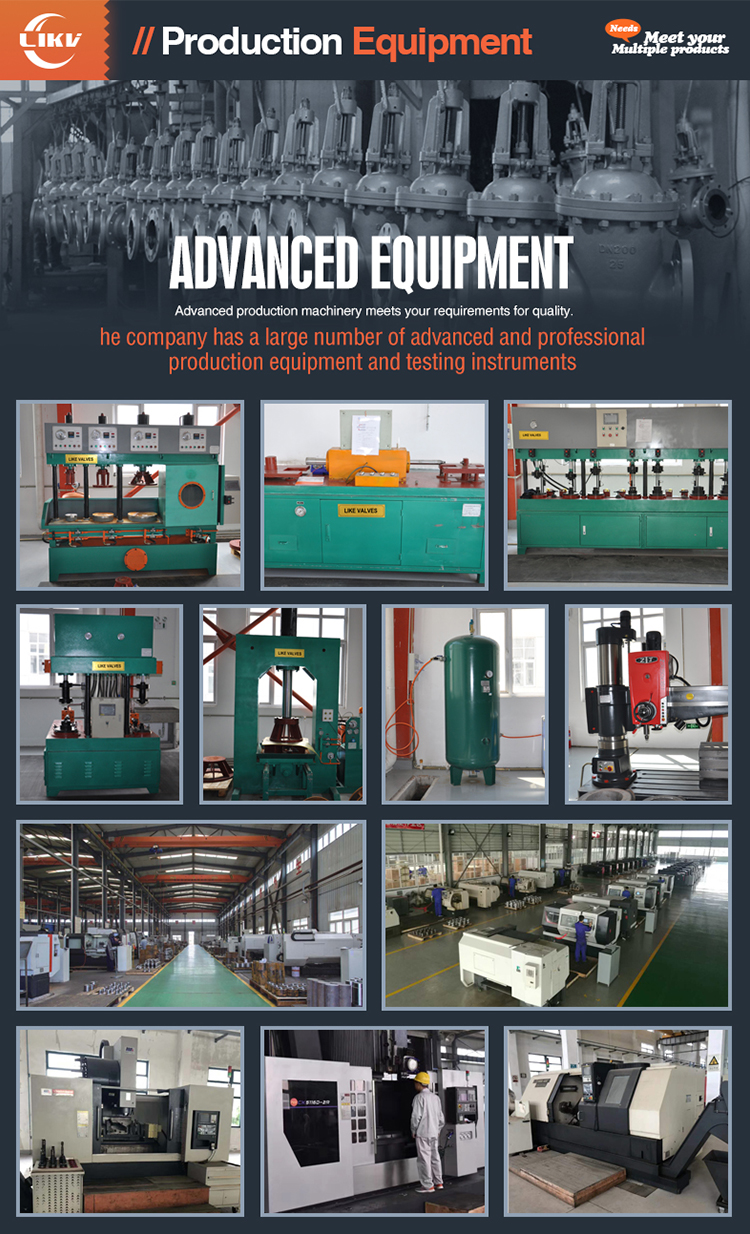

Equipments

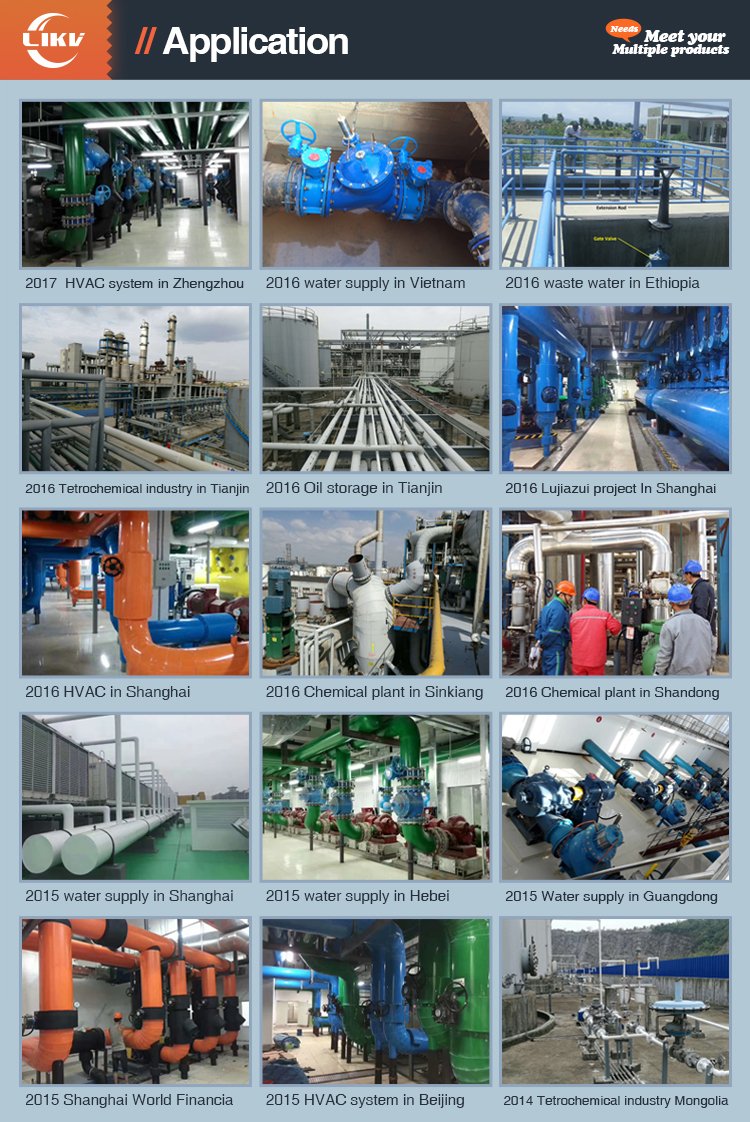

Application