Kev tsim cov txheej txheem thiab kev tswj xyuas cov ntsiab lus ntawm Suav tus qauv flange ntiaj teb li qub

Kev tsim cov txheej txheem thiab kev tswj xyuas cov ntsiab lus ntawm Suav tus qauv flange ntiaj teb li qub

1,Taw qhia

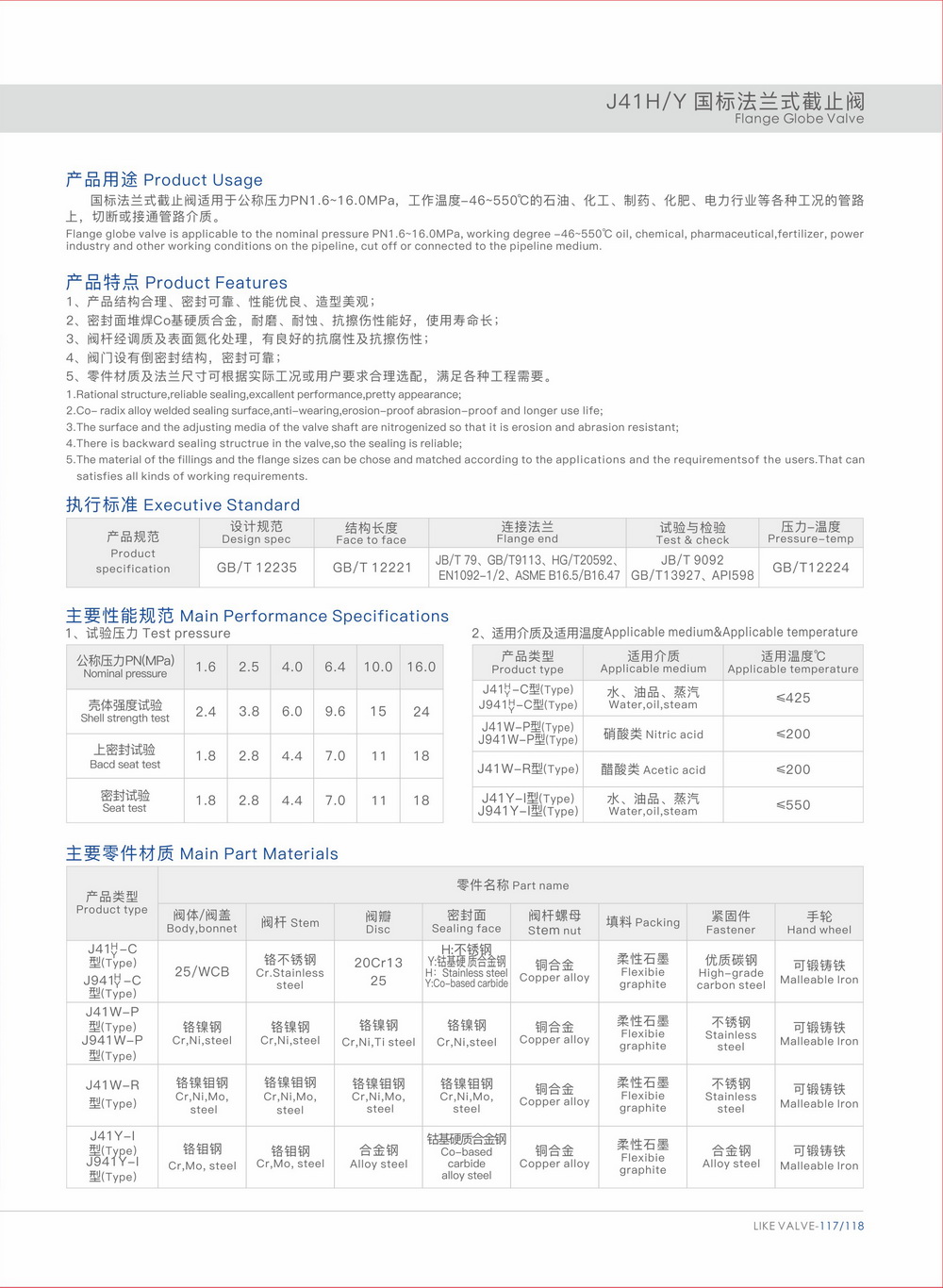

Tuam Tshoj tus qauv flange ntiaj teb valve, raws li cov raj xa dej dav dav, yog siv dav hauv kev lag luam xws li roj av, tshuaj, hluav taws xob, thiab metallurgy. Vim nws cov qauv yooj yim, kev ua tau zoo sealing, thiab lub neej ua haujlwm ntev, nws tau nyiam los ntawm kev ua lag luam. Txawm li cas los xij, hauv cov txheej txheem tsim khoom, yuav ua li cas kom ntseeg tau qhov zoo ntawm flange nres li qub thiab txhim kho cov khoom sib tw tau dhau los ua qhov tseem ceeb ntawm kev saib xyuas rau cov tuam txhab tsim khoom. Tsab ntawv xov xwm no yuav tshawb txog cov khoom lag luam zoo ntawm Suav tus qauv flange ntiaj teb li qub los ntawm ob yam: txheej txheem tsim khoom thiab cov ntsiab lus tswj kom zoo.

2,Kev tsim cov txheej txheem ntawm Suav tus qauv flange ntiaj teb li qub

1. Kev xaiv cov khoom siv

Cov khoom siv yog qhov tseem ceeb cuam tshuam rau qhov zoo ntawm flanged ntiaj teb li qub. Thaum xaiv cov ntaub ntawv, cov ntaub ntawv ntawm cov khoom tseem ceeb xws li lub cev lub cev, lub hau npog, thiab lub valve disc yuav tsum raug xaiv kom tsim nyog raws li qhov kev ua haujlwm, hom nruab nrab, qhov kub thiab txias ntawm lub valve. Nyob rau tib lub sijhawm, kev saib xyuas yuav tsum tau them rau cov tshuaj muaj pes tsawg leeg, cov khoom siv kho tshuab, kev ua haujlwm vuam thiab lwm yam ntsuas ntawm cov khoom kom ntseeg tau tias nws zoo.

2. Valve lub cev casting

Lub cev lub cev yog lub ntsiab lus tseem ceeb ntawm lub ntiaj teb flanged valve, thiab nws qhov zoo cuam tshuam ncaj qha rau kev nyab xeeb ntawm lub valve siv. Nyob rau hauv tus txheej txheem ntawm valve lub cev casting, tsim nyog cov txheej txheem yuav tsum tau saws, xws li xuab zeb casting, poob ua npuas ncauj casting, thiab lwm yam., kom ntseeg tau tias tsis muaj qhov tsis xws luag xws li xuab zeb qhov, pores, thiab slag inclusions nyob rau hauv lub valve lub cev. Nyob rau tib lub sijhawm, nws yog ib qho tsim nyog yuav tsum nruj me ntsis tswj tsis tau xws li kub thiab txias tus nqi thaum lub sij hawm casting txheej txheem kom tsis txhob muaj kev ntxhov siab casting uas cuam tshuam rau qhov tseeb qhov tseeb thiab txhua yam khoom ntawm lub cev valve.

3. Mechanical processing

Mechanical processing yog txheej txheem tseem ceeb los xyuas kom meej qhov tseeb thiab du ntawm flange ntiaj teb li qub. Thaum lub sij hawm machining txheej txheem, high-precision thiab siab rigidity CNC tshuab cuab yeej yuav tsum raug xaiv los xyuas kom meej machining raug. Nyob rau tib lub sijhawm, kev teeb tsa tsim nyog ntawm kev ua tsis tau, xws li txiav ceev, pub tus nqi, thiab lwm yam, tuaj yeem txhim kho kev ua haujlwm zoo thiab txo cov nqi. Tsis tas li ntawd, nws yog ib qho tseem ceeb uas yuav tsum tau xyuam xim rau kev tswj xyuas kom zoo thaum lub sij hawm ua cov txheej txheem, nruj me ntsis tshuaj xyuas qhov loj me, thiab xyuas kom meej cov khoom tsim nyog.

4. Valve sib dhos

Valve sib dhos yog ib kauj ruam tseem ceeb hauv kev ua kom muaj kev sib khi thiab kev pabcuam lub neej ntawm flanged ntiaj teb li qub. Thaum lub sij hawm sib dhos txheej txheem, kev huv huv ntawm cov khoom yuav tsum tau ua kom tsis txhob muaj impurities, roj stains, thiab lwm yam uas yuav cuam tshuam rau kev sib khi. Nyob rau tib lub sijhawm, nws yog ib qho tsim nyog yuav tsum ua raws li cov txheej txheem sib dhos kom ntseeg tau tias qhov tseeb ntawm qhov chaw sib khi xws li valve discs thiab lub rooj zaum valve. Tsis tas li ntawd, kev saib xyuas yuav tsum tau them rau kev xaiv cov sealing gaskets, thiab cov khoom siv gasket tsim nyog yuav tsum raug xaiv raws li kev ua haujlwm ntawm lub valve los txhim kho cov nyhuv sealing.

5. Vuam txheej txheem

Cov txheej txheem vuam muaj qhov cuam tshuam loj rau lub zog thiab kev sib khi ua haujlwm ntawm flange ntiaj teb li qub. Thaum lub sijhawm vuam, cov txheej txheem vuam tsim nyog thiab cov khoom siv yuav tsum raug xaiv, xws li argon arc vuam, hluav taws xob arc vuam, thiab lwm yam. Nyob rau tib lub sijhawm, nws yog ib qho tsim nyog los tswj qhov tsis xws li vuam ceev thiab vuam tam sim no los xyuas kom meej qhov zoo ntawm cov khoom. weld seam. Tsis tas li ntawd, kev kho cua sov yuav tsum tau ua tom qab vuam kom tshem tawm cov kev ntxhov siab ntawm vuam thiab txhim kho cov khoom siv ntawm cov pob qij txha.

3,Cov ntsiab lus tseem ceeb rau kev tswj xyuas zoo ntawm Suav tus qauv flange ntiaj teb li qub

1. Tsim kev tswj kom zoo

Nyob rau theem tsim, nws yuav tsum tau ua tib zoo xav txog yam xws li kev ua haujlwm thiab cov yam ntxwv nruab nrab ntawm lub valve, ua kom zoo dua qub ntawm lub valve, thiab txhim kho kev nyab xeeb thiab kev ntseeg siab ntawm lub valve. Nyob rau tib lub sijhawm, kev saib xyuas yuav tsum tau them nyiaj rau lub zog suav thiab kev sib khi ua haujlwm ntawm lub valve kom ntseeg tau tias nws ua tau raws li qhov xav tau ntawm kev siv hauv lub neej tsim.

2. Kev tswj cov khoom zoo

Kev tswj cov khoom zoo yog lub hauv paus rau kev ua kom zoo ntawm flanged ntiaj teb li qub. Peb yuav tsum ntxiv dag zog rau kev tshuaj xyuas cov khoom siv raw, cov khoom siv sib txuas, cov khoom siv vuam, thiab lwm yam, kom ntseeg tau tias cov ntaub ntawv ua tau raws li lub teb chaws thiab cov qauv kev lag luam. Nyob rau tib lub sijhawm, kev saib xyuas yuav tsum tau them rau qhov zoo ruaj khov ntawm cov ntaub ntawv kom tsis txhob muaj cov khoom lag luam tsis ruaj khov los ntawm kev hloov pauv ntawm cov khoom zoo.

3. Kev tswj xyuas zoo

Thaum lub sij hawm ua, nws yuav tsum nruj me ntsis ua raws li cov txheej txheem specifications kom paub meej machining raug. Txhim khu kev tswj kom zoo ntawm cov txheej txheem tseem ceeb, xws li valve lub cev casting, mechanical processing, vuam, thiab lwm yam., kom ntseeg tau cov khoom zoo. Nyob rau tib lub sijhawm, kev saib xyuas tsis tu ncua thiab kev saib xyuas yuav tsum tau ua ntawm cov khoom siv los txhim kho nws qhov tseeb thiab ua kom cov khoom zoo.

4. Kev tswj xyuas zoo

Kev tswj hwm kev sib dhos zoo yog tus yuam sij kom ntseeg tau tias kev sib khi ua haujlwm thiab kev pabcuam lub neej ntawm flange nres li qub. Thaum lub sij hawm sib dhos txheej txheem, nws yog ib qho tsim nyog yuav tsum ua raws li cov txheej txheem sib dhos kom nruj kom huv si thiab haum qhov tseeb ntawm cov khoom. Ntxiv dag zog rau kev soj ntsuam ntawm qhov sealing nto kom ntseeg tau tias tsis muaj khawb, hnav lossis lwm yam tsis xws luag ntawm qhov sealing nto. Tsis tas li ntawd, kev saib xyuas yuav tsum tau them rau kev xaiv thiab kev teeb tsa ntawm gaskets los txhim kho cov nyhuv sealing.

5. Kev tshuaj xyuas zoo

Kev tshuaj xyuas yog ib kauj ruam tseem ceeb hauv kev ua kom zoo ntawm flanged ntiaj teb li qub. Peb yuav tsum tau ntxiv dag zog rau kev soj ntsuam cov khoom tiav thiab ib nrab ua tiav kom ntseeg tau tias lawv ua tau raws li lub teb chaws thiab cov qauv kev lag luam. Nyob rau tib lub sijhawm, kev saib xyuas yuav tsum tau them nyiaj rau kev cob qhia cov neeg ua haujlwm soj ntsuam txhawm rau txhim kho lawv cov qib tshuaj xyuas thiab zam cov khoom lag luam teeb meem tshwm sim los ntawm tib neeg yam.

4,Xaus

Cov txheej txheem tsim khoom thiab kev tswj xyuas cov ntsiab lus ntawm Suav tus qauv flange ntiaj teb li qub yog qhov tseem ceeb los xyuas kom meej cov khoom zoo. Los ntawm optimizing tsim, xaiv cov ntaub ntawv zoo, nruj me ntsis tswj cov txheej txheem ua thiab sib dhos, thiab ntxiv dag zog rau kev soj ntsuam, qhov zoo ntawm flange ntiaj teb li qub tuaj yeem txhim kho thiab cov khoom sib tw tuaj yeem txhim kho. Cov tuam txhab lag luam yuav tsum tsis tu ncua tshawb nrhiav cov thev naus laus zis tshiab thiab cov txheej txheem, muab cov neeg siv khoom zoo dua thiab txhim khu kev qha ntau dua, thiab pab txhawb rau kev txhim kho ntawm Tuam Tshoj txoj kev lag luam valve.