Product features of electric wedge gate valve

1. The fluid resistance is small, and the sealing surface is eroded and eroded by medium;

2. Easy to open, good sealing performance, unlimited medium flow direction, no disturbance, no pressure drop;

3. The utility model has the advantages of simple shape, good manufacturing technology and wide application range.

Executive standard

| Product specification | design code | Structural length | Connecting flange | Test and inspection | Pressure temperature |

| GB/T12234 | GB/T12221 | JB/T79、GB/T9113HG/T20592、EN1092 | GB/T 13927JB/T9092、API598 | GB/T 12224 |

Main performance specification for electric wedge gate valve

1. Test pressure

| Nominal pressurePN(MPa) | housing | Test pressure(MPa) | Upper seal | |

| Sealing fluid | Seal (gas) | |||

| 1.6 | 2.4 | 1.8 | 0.6 | 1.8 |

| 2.5 | 3.8 | 2.8 | 0.6 | 2.8 |

| 4.0 | 6.0 | 4.4 | 0.6 | 4.4 |

| 6.4 | 9.6 | 7.1 | 0.6 | 7.1 |

| 10.0 | 15.0 | 11.0 | 0.6 | 11.0 |

| 16.0 | 24.0 | 18.0 | 0.6 | 18.0 |

2. Applicable medium and temperature

| Shell material | Applicable medium | Applicable temperature (℃) |

| Carbon steel (type C) | Water, steam, oil | ≤425 |

| Chromium nickel steel (P type) | Nitric acids | ≤200 |

| Cr Ni Mo steel (R type) | Nitric acids | ≤200 |

| Chromium molybdenum steel (type I) | Water, steam, oil | ≤550 |

Material of main parts of electric wedge gate valve

| Body / bonnet | Gate / seat | Stem | Stem nut | filler | handwheel |

| carbon steel | High quality carbon steel + cemented carbide or stainless steel | Chromium stainless steel | copper alloy | Flexible graphite | malleable iron |

| Chromium nickel steel | Stainless steel, stainless steel + cemented carbide | Chromium nickel stainless steel | copper alloy | teflon | malleable iron |

| Cr Ni Mo steel | Stainless steel, stainless steel + cemented carbide | Chromium nickel stainless steel | copper alloy | teflon | malleable iron |

| Chromium molybdenum steel | Alloy steel + cemented carbide | Chromium nickel | copper alloy | Flexible graphite | malleable iron |

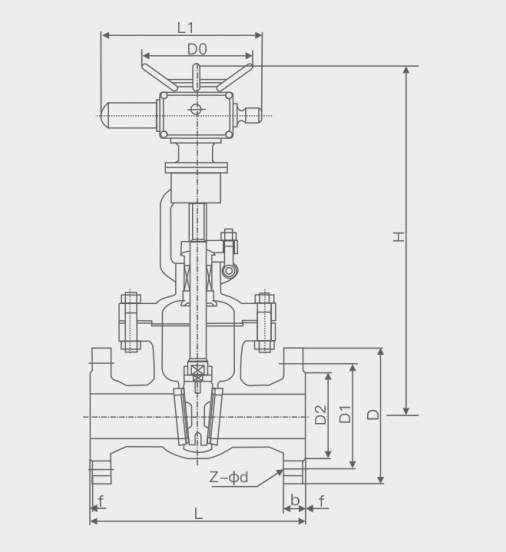

Drawing of electric wedge gate valve

Main connecting dimensions of electric wedge gate valve PN1.6MPa

| DN(mm) | L | D | D1 | D2 | b | f | Z-Φd | H | motor unit | WT(kg) |

|

Z940H Z940 Z940 Z940 -16C Y-16P/R/PL/RL W-16P/R/PL/RL Y-16I Z941Y Z941 Z941 Z941 |

||||||||||

| 40 | 200 | 145 | 110 | 85 | 16 | 3 | 4-18 | 595 | DZW15 | 53 |

| 50 | 250 | 160 | 125 | 100 | 16 | 3 | 4-18 | 653 | DZW20 | 59 |

| 65 | 265 | 180 | 145 | 120 | 18 | 3 | 4-18 | 665 | DZW20 | 62 |

| 80 | 280 | 195 | 160 | 135 | 18 | 3 | 8-18 | 725 | DZW20 | 74 |

| 100 | 300 | 215 | 180 | 155 | 20 | 3 | 8-18 | 787 | DZW20 | 92 |

| 150 | 350 | 280 | 240 | 210 | 24 | 3 | 8-23 | 955 | DZW30 | 161 |

| 200 | 400 | 335 | 295 | 265 | 26 | 3 | 12-23 | 1105 | DZW30 | 219 |

| 250 | 400 | 405 | 355 | 320 | 30 | 3 | 12-25 | 1343 | DZW45 | 376 |

| 300 | 500 | 460 | 410 | 375 | 30 | 3 | 12-25 | 1516 | DZW60 | 484 |

| 350 | 550 | 520 | 470 | 435 | 34 | 4 | 16-25 | 1678 | DZW60 | 695 |

| 400 | 600 | 580 | 525 | 485 | 36 | 4 | 16-30 | 1849 | DZW90 | 977 |

| 450 | 650 | 640 | 585 | 545 | 40 | 4 | 20-30 | 1937 | DZW90 | 1033 |

| 500 | 700 | 705 | 650 | 608 | 44 | 4 | 20-34 | 2234 | DZW120 | 1087 |

| 600 | 800 | 840 | 770 | 718 | 48 | 5 | 20-41 | 2432 | DZW180 | 1357 |

| 700 | 900 | 910 | 840 | 788 | 50 | 5 | 24-41 | 2489 | DZW250 | 1481 |

| 800 | 1000 | 1020 | 950 | 898 | 52 | 5 | 24-41 | 2643 | DZW350 | 1845 |

Main connection dimensions of electric wedge gate valve pn1.62.5mpa

| DN(mm) | L | D | D1 | D2 | b | f | Z-Φd | H | motor unit | WT(kg) |

|

Z940H Z940 Z940 Z940 -25C Y-25P/R/PL/RL W-25P/R/PL/RL Y-25I Z941Y Z941 Z941 Z941 |

||||||||||

| 40 | 200 | 145 | 110 | 85 | 18 | 3 | 4-18 | 595 | DZW15 | 60 |

| 50 | 250 | 160 | 125 | 100 | 20 | 3 | 4-18 | 653 | DZW20 | 64 |

| 65 | 265 | 180 | 145 | 120 | 22 | 3 | 4-18 | 665 | DZW20 | 65 |

| 80 | 280 | 195 | 160 | 135 | 22 | 3 | 8-18 | 725 | DZW20 | 78 |

| 100 | 300 | 230 | 190 | 160 | 24 | 3 | 8-23 | 787 | DZW20 | 98 |

| 125 | 325 | 270 | 220 | 188 | 28 | 3 | 8-25 | 902 | DZW30 | 154 |

| 150 | 350 | 300 | 250 | 218 | 30 | 3 | 8-25 | 955 | DZW30 | 168 |

| 200 | 400 | 360 | 310 | 278 | 34 | 3 | 12-25 | 1105 | DZW45 | 219 |

| 250 | 450 | 425 | 370 | 332 | 36 | 3 | 12-30 | 1343 | DZW45 | 390 |

| 300 | 500 | 485 | 4360 | 390 | 40 | 4 | 16-30 | 1516 | DZW60 | 505 |

| 350 | 550 | 550 | 490 | 448 | 44 | 4 | 16-34 | 1678 | DZW60 | 736 |

| 400 | 600 | 610 | 550 | 505 | 48 | 4 | 16-34 | 1849 | DZW90 | 1027 |

| 450 | 650 | 660 | 600 | 555 | 50 | 4 | 16-34 | 1937 | DZW90 | 1139 |

| 500 | 700 | 730 | 660 | 610 | 52 | 4 | 20-34 | 2234 | DZW120 | 1228 |

| 600 | 800 | 840 | 770 | 718 | 56 | 5 | 20-41 | 2432 | DZW180 | 1502 |

| 700 | 900 | 955 | 875 | 815 | 60 | 5 | 20-41 | 2489 | DZW250 | 1617 |

| 800 | 1000 | 1070 | 990 | 930 | 64 | 5 | 24-48 | 2643 | DZW350 | 1923 |

Main connecting dimensions of electric wedge gate valve PN1.6MPa

| DN(mm) | L | D | D1 | D2 | D6 | b | Z-Φd | f | f2 | H | motor unit | WT(kg) |

|

Z940H Z940 Z940 Z940 -40C Y-40P/R/PL/RL W-40P/R/PL/RL Y-40I Z941Y Z941 Z941 Z941 |

||||||||||||

| 40 | 200 | 145 | 110 | 85 | 76 | 18 | 4-18 | 3 | 4 | 617 | 15 | 62 |

| 50 | 250 | 160 | 125 | 100 | 88 | 20 | 4-18 | 3 | 4 | 665 | 20 | 66 |

| 65 | 280 | 180 | 145 | 120 | 110 | 22 | 8-18 | 3 | 4 | 680 | 20 | 68 |

| 80 | 310 | 195 | 160 | 135 | 121 | 22 | 8-18 | 3 | 4 | 752 | 20 | 80 |

| 100 | 350 | 230 | 190 | 160 | 150 | 24 | 8-23 | 3 | 4.5 | 846 | 30 | 108 |

| 150 | 450 | 300 | 250 | 218 | 204 | 30 | 8-25 | 3 | 4.5 | 1087 | 45 | 258 |

| 200 | 550 | 375 | 320 | 282 | 260 | 38 | 12-30 | 3 | 4.5 | 1243 | 45 | 366 |

| 250 | 650 | 445 | 385 | 345 | 313 | 42 | 12-34 | 3 | 4.5 | 1429 | 60 | 472 |

| 300 | 750 | 510 | 450 | 408 | 364 | 46 | 16-34 | 4 | 4.5 | 1608 | 90 | 673 |

| 350 | 850 | 570 | 510 | 465 | 422 | 52 | 16-34 | 4 | 5 | 1738 | 90 | 804 |

| 400 | 950 | 655 | 585 | 535 | 474 | 58 | 16-41 | 4 | 5 | 1897 | 120 | 1081 |

| 450 | 1050 | 680 | 610 | 560 | 524 | 60 | 20-41 | 4 | 5 | 2104 | 120 | 1259 |

| 500 | 1150 | 755 | 670 | 612 | 576 | 62 | 20-48 | 4 | 5 | 2401 | 180 | 1348 |